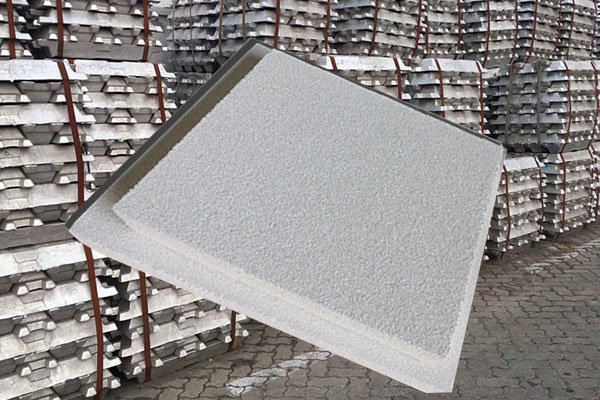

Ceramic Foam Filter Bharat Aluminium has excellent filtering effect on molten Aluminium, and effectively removes oxidized inclusion and other non-metallic inclusion by blocking capture and adsorption using three-dimensional structure. No matter the aluminum bar, aluminum ingot, or aluminum plate casting is filtered, the product quality will be satisfactory.

During the use of Ceramic Foam Filter Bharat Aluminium, two aspects should be considered.

1. Filtration makes liquid aluminum flow orderly and relatively calm, without turbulence.

2. The solid slag in the liquid metal is effectively removed, and the casting quality is rapidly improved.

Ceramic foam filter Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

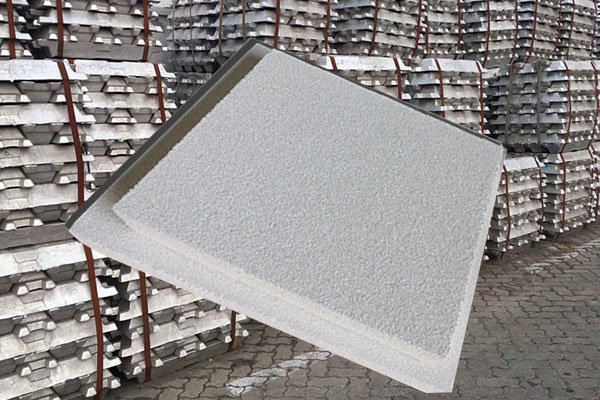

The aluminum ingot casting process is injected into the mold by liquid aluminum, which is the key step of the product quality after cooling into the billet.

The casting process is also a physical process by which liquid aluminum crystallizes into solid aluminum. Casting aluminum ingot process is roughly as follows:

Aluminum out – slag picking – catty check – batching – furnace loading – scouring – casting – aluminum ingot for remelting – finished product inspection – finished product catty check – storage

Aluminum out – slag picking – catty check – batching – furnace loading – refining – casting – alloy ingot – casting alloy ingot – finished product inspection – finished product catty check – storage

The commonly used casting mode is divided into continuous casting and vertical semi-continuous casting.

Continuous casting can be divided into mixed furnace casting and external casting two ways. Continuous casting machines are used. Mixing furnace casting is to pour liquid aluminum into the mixing furnace, which is mainly used for the production of remelting aluminum ingot and casting alloy.

External casting is directly cast by the lifting package to the casting machine, mainly in the casting equipment can not meet the production, or the incoming material quality is too poor to be directly used in the furnace.

Because there is no external heat source, it is required to carry the package with a certain temperature, generally 690 ~ 740℃ in summer, 700 ~ 760℃ in winter, in order to ensure that the aluminum ingot get a better appearance.