Ceramic Foam Filter Boguchany Aluminium is used for separating molten metal from impurities.

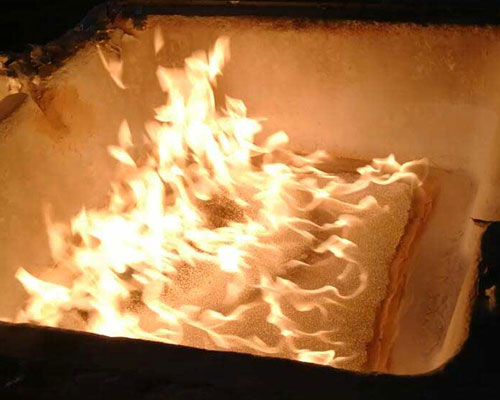

The metallurgical industry needs ceramic foam filters because ceramic foam has low thermal conductivity and high heat resistance, and has a three-dimensional structure with open pores. This structure allows the molten metal to maximize the filtering process.

Ceramic Foam Filter Plate is a kind of effective molten metal filter. It has many advantages large surface area of slags collection, the large inner surface area of filtering, small flow resistance, good filtering effect, etc.

Ceramic Foam Filter can effectively remove all kinds of fineness in the aluminum water to the micron-sized inclusions, so that the aluminum water becomes a smooth laminar flow, which is favorable for filling.

The ceramic filter plate is surrounded by a sealed ceramic fiber gasket, which helps the filter plate to seal in the filter box, ensuring no metal loss. It has a unique corundum structure, good mechanical strength and chemical stability, superior aluminum washability; tightly controlled hole size and through-hole ratio for stable filtration.

Ceramic Foam Filter Boguchany Aluminium can decontaminate the molten metal liquid, simplify the gating system, improve the metallurgical structure of the castings, reduce slag inclusions of the castings, increase the casting quality rate, reduce casting internal defects.

Boguchany Aluminium Smelter is the most modern and environmentally friendly aluminium production in Russia. The smelter is part of the Boguchansky Energy and Metallurgical Complex (BEMO), a unique joint project between RUSAL and RusHydro.

The first metal at the Boguchansky smelter was produced in 2015, and in 2019 the first series of the smelter was officially launched.

Production at Boguchansky smelter meets the latest international environmental requirements for aluminium production and is certified to ISO 14001 international environmental management system standard.

In terms of its design capacity, the Boguchansky Aluminium Smelter ranks third in Russia after the Krasnoyarsk and Bratsk smelters – Boaz is capable of producing almost 600,000 tonnes of aluminium per year. Its production complex consists of two series. The first series has a capacity of 298 thousand tonnes of aluminium per year.

RA-300B grade electrolysers with a capacity of 2.4 tonnes of aluminium per day each are the core of the smelter’s production complex.