Ceramic foam filter China has good room temperature strength, and no slag should be dropped during transportation and operation. Many people do not understand foam ceramics. The development of foam ceramic materials began in the 1970s, and it is a porous material with high temperature characteristics. The size of the hole ranges from nanometer to micrometer, the porosity is between 20% and 95%, and the operating temperature is from room temperature to 1600°C. The following is a small introduction to the performance requirements and applications of Ceramic Foam Filter China.

Performance of Ceramic Foam Filter

- The ceramic foam filter should have good room temperature strength, and no slag should be dropped during transportation and operation.

- It has a certain high temperature strength, thermal shock resistance, and liquid metal erosion resistance.

- Good chemical stability, does not react with liquid alloy.

- It has suitable pore size, good filtering ability for alloy liquid and non-metallic inclusions; good appearance quality: no deformation, small size deviation, uniform pore size, no clogging.

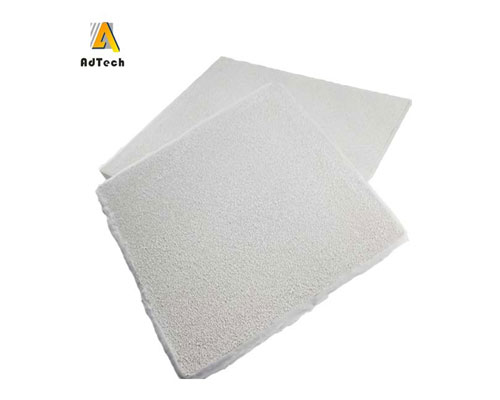

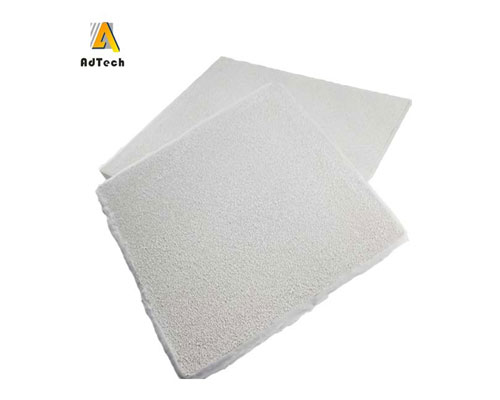

Ceramic Foam Filter China

The Ceramic Foam Filter China has a big filter area, good thermal shock stability, high chemical stability, and good metal scour resistance and filtering efficiency is good, so in the metal melt filtration purification technology, as a new type of high-efficiency filter, get people’s attention. At present, and their applications were expanded to include precision casting, steel casting industry and casting, etc. The foam ceramic filter can improve the mechanical properties of castings, decrease the casting scrap rate, improve casting process product rate, extend the service life of metal cutting processing cutting tool, etc.

Due to the closed cells in the foam ceramics, its thermal efficiency is reduced, and the heat transfer in the convection process is reduced, so that the foam ceramics has the characteristics of low thermal conductivity and good thermal shock resistance. It is an ideal heat-resistant material.

Foam Ceramic Material

At present, The best thermal insulation material in the world is precisely this foam ceramic material. It is widely used in the insulation of space shuttles. Foam ceramics with high specific surface area can be used as heat transfer materials due to the large heat exchange area under high temperature conditions. In addition, it is used as a nuclear thermal insulation material and will not reduce thermal insulation performance due to sea radiation. All in all, foam ceramics, as heat insulation and heat exchange materials, have significant energy-saving effects.