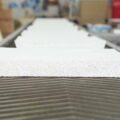

The ceramic foam filter for aluminum casting can effectively remove large inclusions in the liquid aluminum, and absorb micron-sized fine inclusion particles. Ceramic Foam Filters offer a practical and cost-effective alternative to existing systems used in the cast house. It plays a role in improving surface quality, product performance, microstructure, and yield. Molten aluminum filters are widely used in aluminum profiles, aluminum foil, aluminum alloy and other production fields. The foam filter uses a three-dimensional network structure and organic foam cotton connected to the pores as a carrier. Invades it into a special ceramic slurry with thixotropy, and adopts a special rolling process, make the ceramic slurry evenly apply to the skeleton of the carrier. After drying and curing, and then roasting at high temperature.

Ceramic Foam Filter for Aluminum Casting

AdTech offers alumina ceramic foam filters(CFF-PAl) and zirconia foam ceramic filters(CFF-PZr). Ceramic foam filters (CFF) are used to filter and clean aluminum used for beverage can applications, aircraft alloys, and other premium aluminum applications. They are a proven, cost-effective way to remove inclusions from aluminum melts.

Ceramic foam filters are composed of phosphate-bonded, high-purity aluminum that gives each filter cell a high surface area. This high surface area allows the filter to attract inclusion particles much smaller than the cell itself. The reduced cell size leads to a decrease in the metal flow rate, which increases the amount of molten metal in the recommended velocity range. Cell dimensions are tightly controlled in the manufacturing process, leading to consistent filter performance. Installation and maintenance of the filters is simple and can be incorporated into any in-line process system. Alloy changes are easy to perform and there are standardized blue preheat dots on all filters.

AdTech ceramic foam filters have substantial strength at ambient and molten aluminum temperatures, are durable, have high thermal conductivity, and are resistant to chemical attack. They are useful in aluminum gravity casting, pressure die casting, low-pressure, and high-performance sand foundries to remove inclusions. AdTech high-performing foam filters are available in various sizes and grades to improve melt quality and ensure that optimal filtration efficiency is achieved. AdTech also offers aluminum degassing and filtration systems, hot top casting parts, degassing flux.