The ceramic foam filter use is an integral, disposable filter for single casting. The filter has a pore size of 4 to 28 holes per centimeter (10 to 70 holes per linear inch), which corresponds to holes with a diameter of approximately 0.036 to 0.26 cm. Ceramic foam filters are usually produced in square sizes, ranging from 22.86 cm×22.86 cm×5.08 cm (9 in×9 in×2 in) to 66.04 cm×66.04 cm×5.08 cm (26 in×26 in×2 in).

The production of aluminum ingots and billets used to manufacture high-quality aluminum products requires that molten aluminum be relatively free of inclusions, such as insoluble solids or immiscible liquid impurities. In order to ensure that the downstream processed ingots or billets meet the strict requirements for high-quality products, in the entire process of reduction, retention, alloying and casting during the production of molten aluminum, insoluble impurities or inclusions will be generated.

It is desirable to remove inclusions in the final processing step before solidifying the molten aluminum into an ingot or billet by filtration. The industry has been completed in the industry for many years by using a variety of technologies, including bed filtration and ceramic foam filtration, aluminum alloy filtration and fluxing agents.

The open-cell ceramic foam filter for aluminum cast houses was developed in the early 1970s. The technology was first commercially applied in 1974 to produce rolled steel ingots for the manufacture of plates and plates. In the 1980s, ceramic foam filtration technology has been quickly and widely accepted by the market for a variety of high-quality aluminum products, including rigid packaging materials, lithographic printing sheets, aerospace products (such as sheets, plates, forgings, and extrusions), bright finishes, condenser tubes, foils, building profiles, cast alloys and electrical conductor cables and wires. Then the market quickly accepted and developed the technology into aluminum cast houses of various types and levels of complexity.

Ceramic Foam Filter Use

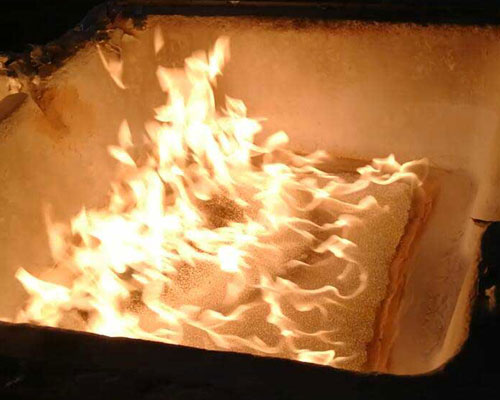

The 17° edge bevel for pouring into the refractory filter box. Fix a fiber paper gasket on the beveled edge to provide a lateral compressive load to secure the filter in the filter box and prevent metal from bypassing the filter edge. The thickness of the fiber gasket material is usually about 0.317 cm to 0.476 cm (1/3 to 3/16 inch), usually composed of silicate fibers, which are added to the gasket material, which expands during heating to increase the pad Sheet pressure. The typical use time in molten aluminum is 30 to 120 minutes.

Advantages of Ceramic Foam Filter

- Easy to use and acceptable to operators;

- Operational flexibility;

- It has drainage capacity after each cast;

- Low variable operating costs;

- Low basic installation cost;

- Effectively remove inclusions;

- The footprint is small, equivale.