The Ceramic Foam Filter Volgograd Aluminum captures aluminum dross from the molten aluminum. This ability is important for maintaining the purity of the ingot. In this way, the quality and productivity of downstream processes such as forging, extrusion and rolling can be guaranteed.

Adtech has always been committed to ensuring that customers can use the highest technology available on the market to produce the highest quality aluminum ingots, aluminum plates, etc. Our technology guarantees the adaptability of the casting quality to the most important application areas of the final product.

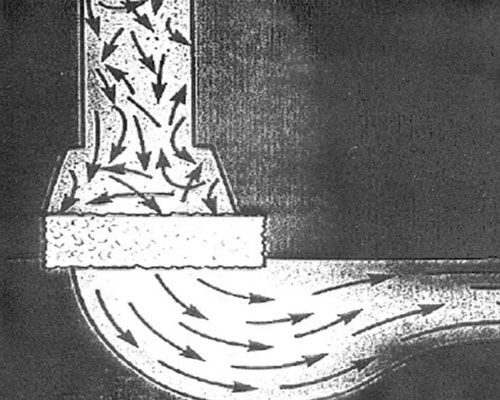

The Ceramic Foam Filter Volgograd Aluminum can remove impurities in the aluminum melt in the form of inclusions. In order to obtain precision casting, it is usually necessary to pass molten metal through a filter to remove these inclusions, capture aluminum dross from the molten aluminum. This ability is important for maintaining the purity of the ingot during the solidification of the metal.

When the Volgograd aluminum alloy liquid flows through the three-dimensional mesh molten metal filter, the inclusions in the melt with a particle size larger than the mesh are blocked by the filter, and the particle size smaller than the filter screen is absorbed by the inner surface of the filter.

Volgograd aluminum smelter was put into use in 1959. The production facilities are served by efficient transportation infrastructure. It is connected to the Federal Railway Network and is close to the Volgograd River Port. This ensures the most efficient system for supplying factory products to RUSAL customers.

The Volga-Don Canal system allows the shipping of raw materials to smelters and facilitates the delivery of finished products to major Russian ports. Allows companies to receive raw materials and transport products by sea.

The main product of the smelter is primary aluminum. The production capacity of VgAZ is 168,000 tons of saleable aluminum per year. The energy for this facility is purchased on the wholesale market.