The purification mechanism of Ceramic Foam Filter Volta Aluminum includes three aspects: interception, adsorption and rectification effect.

One is interception and blocking.

Generally, large-volume inclusions are easily captured by the filter inlet. With the passage of a certain amount of molten metal. A filter cake will form on the surface of the filter inlet. Thereafter, the flow rate of the melt through the filter is significantly reduced. As the inner diameter of the inlet decreases, the probability of interception of smaller-sized inclusions increases, and the removal efficiency of small-sized inclusions increases. Interception and blocking are physical methods to filter out inclusions, which have a good effect on inclusion particles above 50um, while small particles below 40um need to be removed with the help of an adsorption mechanism.

The second is adsorption.

The inclusions are driven by the liquid flow to approach the wall of the molten metal filter, because the two infiltrate and adhere to each other, usually the inclusions and the molten metal are not infiltrated, especially the smaller the particle size of the inclusions, the worse the wettability. Once the inclusions are in contact with the filter surface with relatively better wettability, it is easy to break away from the molten metal and be adsorbed by this surface. If the pore of the filter is smaller, the filter channel is longer, and the flow rate is slow enough. The more likely the inclusions in the molten metal will move to the inner wall of the filter, that is, the higher the efficiency of the inclusions being captured by the filter.

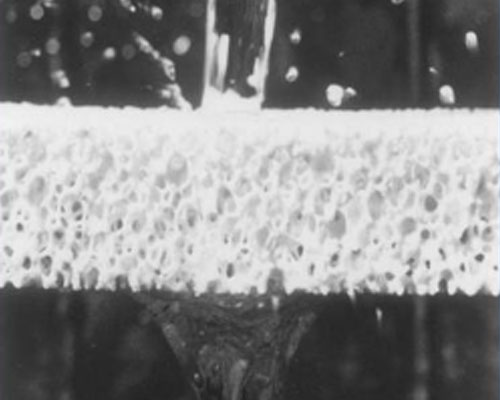

The third is the rectification effect.

The rectifying ability of the filter makes the molten metal, which originally has a strong turbulent flow, in a laminar flow state when flowing through the filter. After flowing through the filter, to restore the original turbulent state, a longer transition zone is required. In this transition zone, the secondary oxidation of the molten metal and the scouring effect on the mold are avoided, thereby playing an obvious slag blocking effect.

Ceramic Foam Filter helps the Volta Aluminum get more pure molten aluminum. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

The aluminum smelter of Volta Aluminum Corporation (VALCO) in Ghana is the first world industrial park in a developing country. VALCO’s rated production capacity is 200,000 metric tons of primary aluminum per year; however, currently, the company only operates 20% of it, and to build a facility of this scale and capacity, currently requires an investment of 1.2 billion US dollars.

VALCO is a limited liability company owned by the Government of Ghana, and it continues to play a key role in the efforts of the Government of Ghana to develop the Integrated Aluminum Industry (IAI). Using VALCO as the backbone of the IAI project, Ghana is preparing to add value to its more than 700 million tons of bauxite deposits in Kibi and Nyinahin, creating more than US$1.05 trillion in value, and creating approximately 2.3 million good and sustainable jobs. Research on the feasibility of the VALCO smelter confirms that VALCO will become the mainstream of Ghana’s development agenda and will become the true pillar of Ghana’s integrated aluminum industry.

VALCO is currently an active force in the downstream aluminum industry in Ghana through metal supply and related employment benefits. In addition, VALCO’s positioning can also meet the expected growth of Ghana’s aluminum downstream industry.