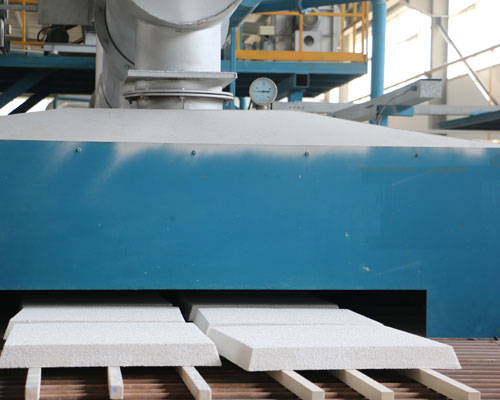

Ceramic Foam Filters Manufacturing Process includes adding pore former process, foaming process, Sol-Gel process, solid particle sintering process, particle accumulation process, Gel injection molding process, etc.

Ceramic Foam Filters Manufacturing Process

Adding Pore Former Process

The process of adding the pore former is to add the pore former to the pottery ingredients, and use the pore former to occupy a certain space in the body. Then after sintering, the pore former forms a porous ceramic foam from the substrate. This process can be made into a porous ceramic foam structure with complex shapes and various shapes, but the disadvantage is poor controllability and low porosity distribution.

Foaming Process

The foaming process is to add organic or inorganic chemical substances to the ceramic components, generate volatile gases through chemical reactions, and fire them into porous ceramics after drying. The advantage of the foaming process is that it is easy to control the shape, composition and density of the product, and is particularly suitable for preparing closed-cell ceramic materials. However, the manufacturing process of the foam ceramic is complicated and difficult to control, and the foam ceramic powder is easy to peel off and contains a large number of closed cells, so it is rarely used in actual preparation.

Sol-Gel Method

The sol-gel method, which is mainly used to prepare nano-scale microporous ceramic materials, and at the same time, through an improved process, high-purity foam ceramic materials can be prepared. Using sol-gel technology to prepare foam, the viscosity of the system increases rapidly during the conversion of sol to gel, thereby stabilizing the bubbles generated in the early stage and facilitating foaming. This process can prepare a foamed ceramic film with nanometer pore size and uniform pore distribution, but the product shape is limited to a certain extent.

Solid-Phase Sintering Process

The solid-phase sintering process, which uses the characteristics of easy sintering of fine particles. The fine particles of the same composition are added to the aggregate. The fine particles evaporate and migrate at a certain temperature and sinter and connect in the large particles. Connect large particles. Because each crystal grain aggregates with other particles at only a few points, a large number of three-dimensional through-holes are formed in the sintered body of ceramic foam filter.

Extrusion Process

The extrusion process is one of the most commonly used methods for preparing porous ceramic honeycomb filter. The porous ceramic body produced by the process has uniform pore size, shape and porosity, and is suitable for mass production, but it is difficult to prepare small pore size products. In the preparation process, extrusion molding is the core process. The process can accurately design the shape and aperture of the hole according to the needs, but does not form a complex channel structure and a material with a smaller aperture. At the same time, it has higher requirements for plastic materials.

Extrusion Process Process

The process of particle accumulation to form pores, which relies on the accumulation of coarser particles to form an integrated granular porous structure. Coarse particles are bonded with fine particles of melt adhesive, and can also be used in combination with fusible adhesives. This technology can be used to adjust the fineness of the particles to the pore structure. The porosity of the product is usually 20% to 30%. Porosity such as powder and starch are added to the raw materials to volatilize at high temperature to increase the porosity to 75%.

Gel Injection Molding Process

Gel injection molding process, which is a new type of molding method that is widely used. Using non-porous molds, the ceramic slurry is solidified in situ to form a solidified body by the chemical reaction inside the slurry or a small amount of additives, and a green body with good microscopic uniformity and higher density is obtained, thereby improving the reliability of the casting. As a new method of making porous ceramics, the foaming of the suspension is the most economical, and the green body formed by in-situ polymerization and solidification has an internal network structure and high strength.