Ceramic Foam Filter (CFF) for aluminum casting is mainly for the filtration of aluminum and alloys in foundries and cast houses. With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to the bottom-line profit.

Ceramic foam filter, depending on the materials: alumina foam ceramic filters, silicon carbide ceramic foam filter, zirconia ceramic foam filter, and magnesium oxide foam ceramic filter.

In the bronze casting process, the use of silicon carbide ceramic foam filter material is of SiC.

Steel castings use zirconia ceramic foam filters. Zirconia ceramic foam filter material is ZrO2 zirconia. Zirconia heat-resistant temperature of the filter is higher than about 1760 ° C, with very high strength and excellent high-temperature impact.

Ceramic foam filter CFF products for aluminum casting effectively remove solid-state mixed with the molten metal, so aluminum alloy can be successfully forged, aluminum foil manufacturing, extrusion processing technology, perfect aluminum products. 10ppi coarse porosity 70ppi of fine porosity range of options

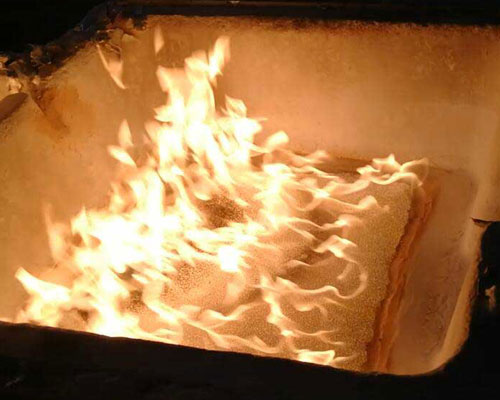

Alumina ceramic foam filters are normally applied by placing them into a filter box. It is important to pre-heat both filter and filter box before use. During pre-heat care must be taken to control both heat up rate and temperature distribution. This minimizes thermal shock and stresses in the filters and filter box refractory.

Before a CFF filter can be used, it must be completely wetted by liquid metal. This happens during the start-up of the casting operation. The amount of metallostatic pressure (or priming head) required to wet filters depends on alloy, metal temperature, pre-heat uniformity, pre-heat temperature, incoming metal quality,pre-filter treatments and on the cell size of the filter.