CFF for Foundry is a high quality filter used in molten aluminum, copper based alloys and ferrous metals (including gray alloys, ductile alloys and steel alloys). The filter consists of an impregnated foam in a controllable opening filter structure. CFF for Foundry can effectively remove oxides and nonmetallic particles.

The maximum temperature of zirconia ceramic filter is 1704 ° C (3100 ° f). These filters are fully sintered ceramic materials with excellent thermomechanical properties. Zirconia ceramic filters can be used in gate, runner, tunnel and pouring cup for investment, sand, shell and permanent molding process.

The maximum temperature of silicon carbide ceramic filter is 1500 ° C (2732 ° f). These filters have excellent thermal conductivity, stability and resistance to sudden temperature changes. Silicon carbide filter can be used in the filter chamber of gate system and poured directly on the filter. They are commonly used in copper based and ferroalloys.

The maximum temperature of alumina ceramic foam filter is 1350 ° C (2462 ° f). These filters can be used in the filter chamber of the gating system and can be immersed in molten metal.

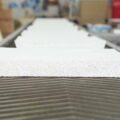

The foundry of beckor Aluminum Inc has developed a filtration method that allows the foam ceramic filter to be reused for multiple castings. The CFF filter box contains two parallel filters that are immersed in the molten metal between the castings. Rules have been developed to specify the maximum allowable tonnage through the filter based on alloy and product. Automation and casting practices minimize the possibility of filter release.

AdTech CFF for Foundry can effectively remove large inclusions in the aluminum liquid, and effectively adsorb small inclusions of small size. No slag, no pollution to the aluminum liquid. Good thermal shock resistance. Automated assembly line production, three calibration procedures, high accuracy of product dimensions. Improve the surface quality of aluminum ingots, aluminum rods, and aluminum coils, improve product performance, and improve the microstructure.