Ceramic foam filters (CFFs) molten aluminum filtration can not only effectively remove a large number of foreign impurities in molten aluminum, but also filter out fine inclusions of a few microns that cannot be removed by traditional processes.

Hydrogen atoms and other harmful ions in molten aluminum are usually adsorbed on inclusions, and the inclusions can become the core of bubble formation. Therefore, while filtering out the inclusions, it can also reduce the content of these harmful elements and gases in the aluminum liquid. Some studies also believe that the filter disc will filter out many small inclusions, thereby reducing the effective crystal nuclei required for the solidification of molten aluminum. Under large undercooling conditions, it can promote the growth of aluminum cores, refine the structure, and improve product performance.

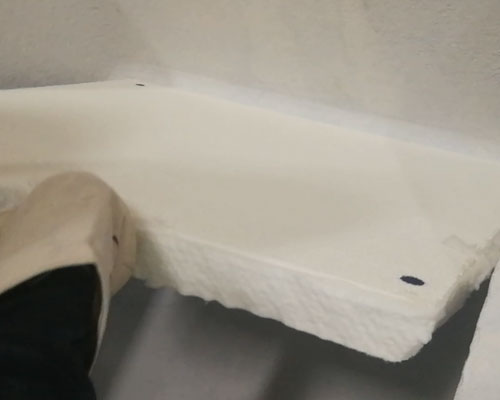

The ceramic foam filter manufacturing method is to immerse polyurethane sponge in ceramic mud, squeeze out the excess material and dry it. Finally, it is sintered at high temperature to form a three-dimensional porous ceramic material, which is a curved and interconnected tube with uneven thickness. It is this uneven tube wall that plays a key role in capturing the small inclusions in the aluminum melt. This structure also increases the chance of aluminum melt contacting the ceramic part of the filter, thereby increasing the possibility of inclusions being adsorbed.

CFFs Molten Aluminium Filtration

- The filtration of aluminum alloy melt includes surface filtration and internal filtration.

- Surface filtration means that solid impurities are mainly deposited on the surface of the ceramic foam filter.

- Internal filtration means that molten aluminum carries inclusions in the filter medium along the tortuous channels and pores. These inclusions are directly intercepted, adsorbed, deposited, etc., collide with the pore wall, and firmly adhere to the pore wall.

- As the filtration progresses, the effective filtration area of the pores gradually decreases, the permeability decreases, and the filtration accuracy improves.

- Ceramic foam filters (CFFs) and deep bed filtration belong to internal filtration, while tubular filtration belongs to double capture of surface and internal impurities.

Ceramic foam filters Cffs molten aluminum filtration are widely used in the production of large aluminum processing enterprises in Russia, the Middle East, and Southeast Asia. During use, it is not only necessary to remove the inclusions in the aluminum melt, but also to avoid clogging the ceramic foam filter Cff and increase the service life of the CFF.