Characteristics of Porous Ceramics

1. Thermal shock stability

Foam ceramics are often used on occasions where the temperature changes rapidly, and must have good thermal shock resistance. The performance of the foam ceramic products made by Shandong Industrial Ceramics Research and Design Institute is shown in Tables 1-3. Thermal stability and expansion coefficient of surface ceramic porous(×106/℃) Material thermal stability Expansion coefficient A (1000℃ cordierite 000℃ ~ room temperature 8 cycles mullite ℃ ~ room temperature 5 cycles alumina ℃ ~ room temperature 5 In short, the characteristics of porous ceramics themselves determine that they generally have the following general characteristics: good mechanical strength and stiffness, and the shape and size of ceramic porous will not change under the action of air pressure, hydraulic pressure and other stresses.

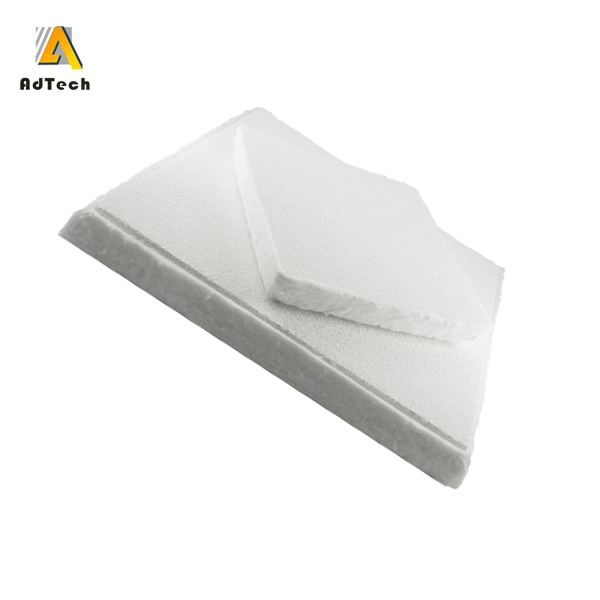

2. High porosity

The porosity is usually between 30~90vol%, and even up to 95vol%3. It has a high specific surface area and the distribution of the pores is relatively uniform, and the porous ceramic products with the selected pore size can be produced within the pore size range of 0.05~600μum. The heat resistance is better than that of porous metal materials and porous polymer materials. ceramic porous made of high-temperature resistant materials are used to filter molten steel or high-temperature gas.

3. Good chemical stability, through material selection and process control, can be used in various corrosion Environmental characteristics of porous ceramics.

But the most notable feature of ceramic porous is high porosity, and its pore surface, shape, size, and distribution can be adjusted.

Applications of Porous Ceramics

ceramic porous is widely used in metallurgy, the chemical industry, environmental protection, energy, food, pharmaceutical biology, and other fields due to their excellent properties for filtration, separation, air distribution, sound absorption, and heat insulation, chemical fillers, bioceramics and catalyst carriers.

1. Filtration and separation

Filtration is the separation of solid particles suspended in a liquid or gas or two immiscible liquids. The filter device composed of plate or tubular products of ceramic porous has the characteristics of a large filtering area and high filtering efficiency, and the porous ceramics itself has the features of high-temperature resistance, wear resistance, corrosion resistance, high mechanical strength, no pollution to the filtered liquid and easy regeneration. It not only plays a vital role in the filtration and separation of general fluids but also plays a unique role in some special fields.

①Preparation and sterilization of ultrapure water Porous ceramic filter elements made of diatomite or clay clinker have been used for sterilization and purification of drinking water, oil well injection water, etc., and also used for disinfection and filtration of injections. And the purification of ultrapure water for the electronics industry, pharmaceutical industry, optical lens grinding, etc.

②Porous ceramics for wastewater treatment to filter industrial wastewater and domestic sewage have become an important development direction for wastewater treatment and purification. It is suitable for all kinds of polluted wastewater with high efficiency and low cost.

③The strong corrosion resistance of ceramic porous for the filtration of corrosive fluids makes it show unique advantages in the filtration of corrosive liquids or gases such as acid and alkali.

④ Molten Metal Filtration