The production of cold-rolled aluminum plates and strips all need to go through the production processes of cold rolling, finishing and heat treatment. The difference in production process is mainly in the production method of cold-rolled billets. At present, there are mainly three production processes, casting and rolling, slab hot rolling and continuous casting and rolling process.

The casting-rolling process is to directly cast molten aluminum into 6mm-8mm cast-rolled coils, and then cold-roll them.

The hot-rolling process of slab is to semi-continuously cast molten aluminum into large slabs. The slabs are first sent to the hot rolling mill to be processed into hot-rolled coils and then cold-rolled after cutting the head and tail, face milling, and heating. According to factors such as product type and output, hot rolling can be divided into multiple forms such as single-stand double coiling, hot rough rolling + hot finishing (1 or 3 to 5 stands are acceptable).

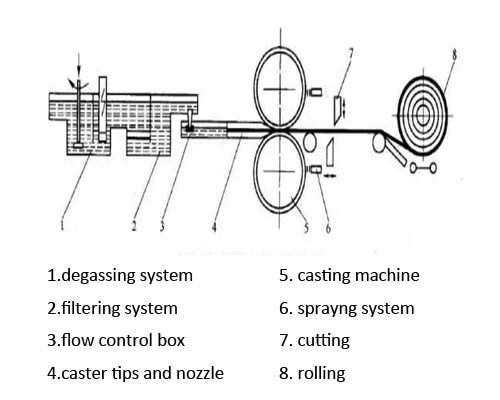

The continuous casting and rolling process is between the casting and rolling process and the slab hot rolling process, and has many forms. Generally, molten aluminum is continuously cast into slabs of a certain specification (thickness is much thinner than large slabs), and the high-temperature slabs are continuously sent to the hot rolling mill for rolling.

In recent years, with the commissioning of multiple domestic aluminum processing production lines, the homogeneity competition in the aluminum strip market has been severe, product prices have fallen sharply, and production capacity has not been fully utilized. Under this situation, the thin slab continuous casting and rolling process, which saves energy and reduces consumption and reduces production costs, has attracted more and more attention. For example, for the production of 1mm~2mm aluminum, the continuous casting and rolling process only needs smelting, continuous casting and rolling to achieve. The casting-rolling process needs to be smelted, cast-rolled, and cold-rolled. The slab hot rolling process requires smelting, semi-continuous casting, sawing, milling, ingot heating, rolling.

The continuous casting and rolling process is a short process, low-cost production of aluminum alloy strip technology, the key technology is high-speed casting and rolling technology. The biggest problem of the continuous casting and rolling process at this stage is the surface quality and product stability. Therefore, during production, special attention should be paid to the temperature of the molten metal, the grain refiner, the cleanliness of molten metal, and the hydrogen content during the smelting process. The continuous casting and rolling production line is best to be close to the electrolytic aluminum plant, the most important thing is to meet the production.