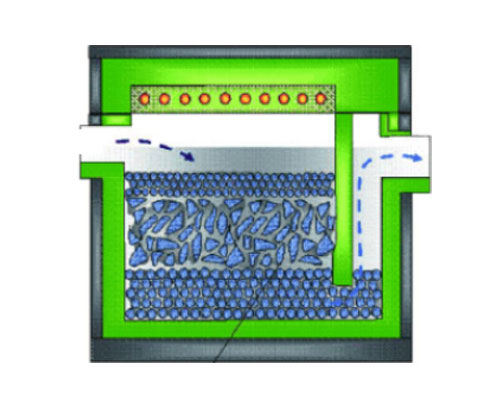

Ceramic foam filter filtration(CFF), cartridge filtration, and the deep bed filter system(PDBF) are the main three kinds of aluminum filtration methods. The DB filtering device is made up of multiple layers of alumina balls and a layer of alumina gravel of appropriate size stacked uniquely, and the thickness of the filter medium reaches 500 mm.

Description

Ceramic foam filter filtration(CFF), cartridge filtration, and the DBfilter system(PDBF) are the main three kinds of aluminum filtration methods. The db filtering device is made up of multiple layers of alumina balls and a layer of alumina gravel of appropriate size stacked uniquely, and the thickness of the filter medium reaches 500 mm. The size and stacking method of alumina balls and gravel should be adjusted according to different alloys. Inclusions are mainly adsorbed on the surface of the medium in four ways: direct interception, Brownian motion, inertial force, and gravitational precipitation.

The feature

The DB filter has those four advantages and one disadvantage.

Advantages

1. The best filtering effect.

2. Only deep bed filters can be used for filtering alloy aluminum liquid.

3. Low running cost of the filtration process.

4. Biggest filtering capacity.

Disadvantages

1. Highest purchase cost.

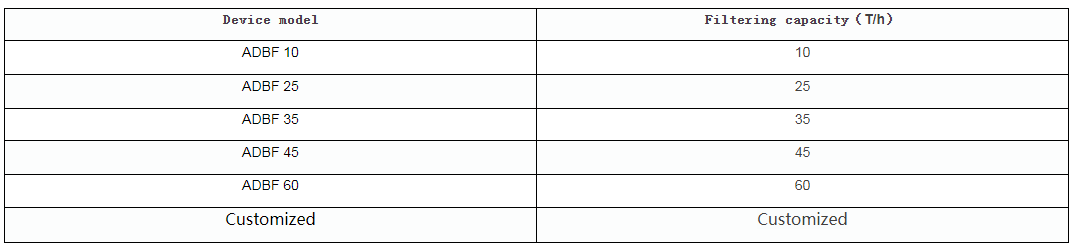

Parameter

application

Applying for filtering 1-8 series alloy aluminum

The dB filter is the most efficient aluminum filtration system, which is widely applied in the high-precision aluminum casting industry, such as aerospace aluminum alloy materials supplying.

Application

Parameters

Alloy aluminum filtering range Series 1-8

Aluminum liquid temperature 700-760