At the deep bed filter device outlet, the melt’s quality is better after a series of online treatments such as degassing and filtering. The slag sample is relatively clean, and there are a small number of inclusions at the interface of the filter and the melt.

In the initial casting stage of the deep bed filter, the ability to intercept inclusions is relatively weak, and then as the filtering tonnage increases, the number of inclusions in the melt gradually decreases, and the filtration efficiency increases.

In the slagging at the outlet of the deep bed filter, a variety of small-sized inclusions were found, and these small-sized inclusions are at risk of being mixed into the melt during the casting process. The presence of inclusions in the slagging at the entrance and exit indicates the necessity of regular maintenance and cleaning during the use of the deep bed filter.

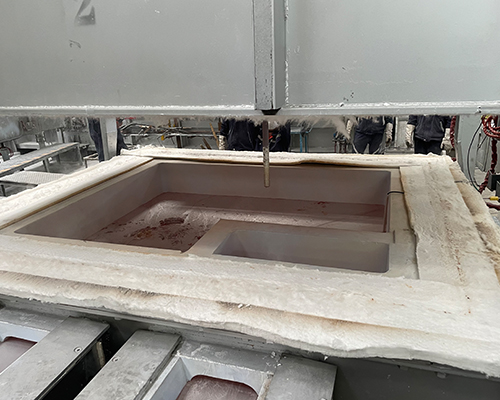

The deep bed filter device is made up of multiple layers of alumina balls and a layer of alumina gravel of appropriate size stacked uniquely, and the thickness of the filter medium reaches 500 mm. The size and stacking method of alumina balls and gravel should be adjusted according to different alloys. Inclusions are mainly adsorbed on the surface of the medium in four ways: direct interception, Brownian motion, inertial force, and gravitational precipitation.

3104 aluminum alloy needs to be processed by hot rolling, cold rolling, and deep drawing in the production process of cans, which requires high melt quality and ingot quality. In production, more advanced filters are usually used for melt purification. For processing, the deep bed filter is one of the commonly used filters.

This deep filtration technology has been recognized in the casting field and can meet the needs of high-end products with higher quality requirements. The deep bed filter has the advantages of low production cost, large filtration area, and high filtration efficiency. For impurities greater than 5um, the filtration efficiency is greater than 90%. How to use deep bed filters efficiently directly affects product quality, production efficiency, and cost.