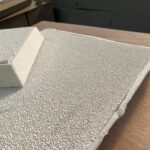

Description of porous ceramic filter quality improvement

Since the strict testing in the laboratory, the ceramic foam filter has failed to meet the standard twice in 70-mesh strength batches, and the number of unqualified batches in the two batches was about 1,500 pieces; this kind of unqualified batch is a phenomenon of unstable strength. One piece of random inspection fails to meet the standard, and the unqualified re-inspection sometimes passes and can be put into storage again, and sometimes the re-submission is unqualified, and this product cannot be put into storage; the analysis reasons are as follows:

1. The pulping of the pulping machine is uneven, resulting in uneven compressive strength, many of which are low, and the average value is not up to standard;

2. During the cooling and debugging process of the new roller kiln, a batch was unqualified, and the temperature instability of the new kiln caused the abnormal sintering process of the product;

3. The viscosity of the slurry is unstable, which leads to the instability of the porous ceramic filter. The amount of water added to the ingredients of the same specification on the same day has been changing, and the amount of change is large; the instability of raw materials is the direct cause of the unstable viscosity of the slurry.

After this problem occurred, the material workshop staff team made a timely cause analysis and timely rectification methods. According to the cause of unqualified product problems, the content and method of timely rectification work. Improve product quality, so as to be more refined and stronger.

Adtech specializes in the production of ceramic foam filters and degassing unit