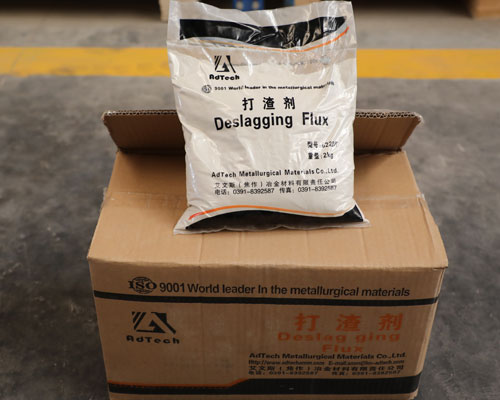

The purification of molten aluminum includes all aspects of raw material, smelting, standing, degassing, slag removal and filtration. The cleanliness of molten aluminum or the size and content of slag inclusions will seriously affect product quality. AdTech Deslagging Flux for Aluminium and refining fluxes have been widely used in most aluminum foundries, and the slag removal effect is excellent. They provide quality assurance for the next aluminum alloy casting.

Aluminum alloy starts to melt at around 600°C, and will melt when heated to 660°C. The melting temperature should not exceed 760°C. When the melting temperature exceeds 770°C, the aluminum alloy will be severely oxidized, hydrogen absorption and slag inclusions during the melting process will increase, and coarse grains will appear during the casting and solidification process, thereby reducing the mechanical properties.

In order to reduce the oxidation of the aluminum alloy during the melting process, 0.4% to 0.5% of the covering agent is added during the melting process to protect the aluminum oxide film from damage. The type of covering agent is similar to the chemical composition of the slag cleaner.

After the smelting is completed, there are a lot of scum on the surface of the aluminum alloy, mainly Al2O3 and other oxide inclusions. These small inclusions are heavier than aluminum liquid, but after agglomeration and agglomeration, the specific gravity is lighter and floats on the surface, requiring slag removal. Add the slag remover in the amount of 0.2%~0.5%, sprinkle it evenly on the surface of the molten aluminum, and perform shallow and uniform stirring. After the slag is allowed to stand for a few minutes, the aluminum slag can be smoothly removed from the furnace door.

On the one hand, the Deslagging Flux for Aluminium has a heating effect and can melt the aluminum liquid attached to the slag; on the other hand, the deslagging flux can effectively separate the slag and the aluminum liquid, which is beneficial to the slag.

AdTech also provides on-line degassing device and CFF filter system, which have been widely used in most aluminum foundries with better purification effect. They provide quality assurance for the next aluminum alloy casting.