Electrolytic aluminum liquid features include high temperature, more oxidation inclusions, high hydrogen content, and metal and Na content.

Electrolytic Aluminum Liquid Features

(1) The temperature is high. The electrolysis process is usually carried out at a temperature of 950-970℃, which is determined by the properties of the cryolite-alumina melt composed of electrolyte and alumina, so the temperature of the molten aluminum in the electrolytic cell is at least 940℃. Such a high temperature, coupled with the large amount of aluminum liquid taken out of the electrolytic cell, has a long enough time to keep the aluminum in a liquid state, and the aluminum storage tank can be transported after repeated aluminum extraction operations on several electrolytic cells. Until the molten aluminum in the foundry workshop is transferred to the holding furnace, the high temperature above 850℃ is maintained.

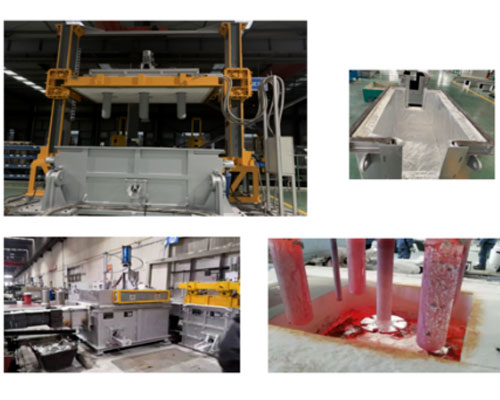

(2) There are many oxidation inclusions. Although there is a certain density difference between the cryolite-alumina molten salt electrolyte and the aluminum liquid at the same temperature (the former is about 21g/cm3, the latter is about 23g/cm3), it is enough to ensure that the aluminum liquid and the electrolyte are layered. But because the difference is very small, a small amount of electrolyte will inevitably be absorbed when the aluminum is picked up by vacuum. In addition to the intense stirring and circulation during the electrolysis process, the sharp movement of the aluminum liquid causes the aluminum to oxidize again in the anode space, resulting in There are more oxidized inclusions in the aluminum melt, including the aluminum oxide deposited on the bottom of the electrolytic cell and the aluminum carbide produced by the diffusion of carbon, which makes the various inclusions in the aluminum liquid relatively high. AdTech CFF filtering unit is used to remove oxidation inclusions.

(3) Fe Si content is high. In the electrolysis process, the oxide impurities of elements with positive potentials, such as SiO2, Fe2O3, etc., are easily reduced, while the reduced impurity elements such as Fe and Si directly enter the aluminum liquid, which reduces the aluminum grade. They mainly come from raw alumina, carbon anodes and operating tools. Especially when domestic alumina is used as the raw material, the Si content in alumina is generally higher than that of imported alumina due to the type of ore and desilication technology in China. Usually the aluminum liquid contains (Si) 0.8%-10%, (Fe ) 0.9%~1.1%.

4) High hydrogen content. Due to the particularity of the palladium electrolysis process, it is inevitable that the molten aluminum contains gas. The main component of the gas is hydrogen, about 70% to 90%, and a small amount of CO, CO2, N2 and CH4. The radon produced by the thermal decomposition of the anode hydrocarbons is electrochemically dissolved on the anode. After the generated H migrates to the cathode, it is discharged on the cathode to generate hydrogen. In addition, the hydrogen in the surrounding environment is reduced by the water vapor from the aluminum to dissolve in the aluminum. In liquid, the saturated content of hydrogen in liquid aluminum increases with the increase of temperature. For example, it is 0.67mL/100gAl at 660℃, 1.23mL/100gAl at 750℃, and 2.15m/100gAl at 850℃. It is 2.9m/100gAl at 950℃ and 3.9mL/100gAl at 1000℃. AdTech offers online degassing unit for hydrogen removal.

(5) High Na content. During the electrolysis process, on the one hand, aluminum replaces Na from cryolite (NaAF6), sodium fluoride (NaF) and other media. On the other hand, because the activity of Na in the melt is higher than that of Al, there is Na at the cathode. The precipitation enters the aluminum liquid, so that the content of the aluminum liquid reaches (Na) 0.011%-0.05%.