The filter must be able to form a suitable geometric shape. In addition, the filter material must have unique strength and chemical resistance to filter the conditions of the filter material.

The filter can be manufactured from a sponge shaped to the required size. The sponge can be used as a mesh medium to capture particles from molten aluminum.

To make the filter more effective, a coating that becomes viscous at the temperature of the molten aluminum can be applied to the filter.

In the filtration mode, the coating (such as borosilicate) or low-temperature hot spot materials (such as glass-based materials) can be infiltrated and filtered. When particles in the melt contact the coating on the device, they will prevent the particles in the filter from falling off and contaminating the melt.

For anyone familiar with the refractory materials used to contain molten aluminum and its alloys, the use of alumina particles in ceramic foam filters seems to be an obvious choice. Alumina is relatively chemically inert in molten aluminum, and it is a common alloy, including those containing magnesium. It is also widely used as a particulate material in refractory materials used in furnaces to melt and maintain molten aluminum alloys.

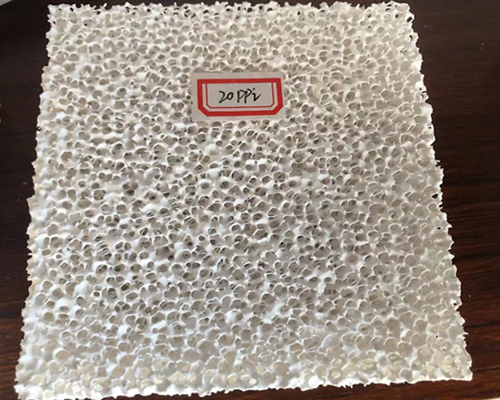

AdTech provides an alumina filter for molten aluminum, which has high thermal shock resistance, high corrosion resistance, sufficient strength, economical production, is more environmentally friendly than existing technologies, and has low density. The ceramic foam filter is proven to resist the chemical attack of molten aluminum alloy. The ceramic foam filter is light in weight and preferably has a density of about 0.25-0.40 g/cc.

Alumina ceramic foam filter is mainly for filtration of molten aluminum and aluminum alloys in foundries and cast houses. With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.