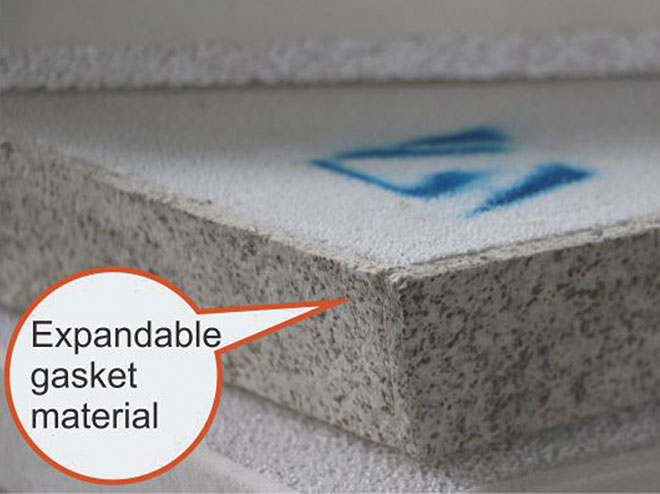

The plate filter units can be sealed by gaskets around their edges. The plate filter unit is preferably sealed by an edge seal along the chamfered outer peripheral surface of the filter plate, thereby providing a reliable seal.

In the continuous casting process, the aluminum liquid filtration can adopt a parallel arrangement of two or more filters. In such operations, the large lengths involved and the associated large total metal flow may require the filter to be replaced midway through the operation. This change can be achieved through the use of filter boxes, each channel contains a filter unit, a device that transfers the flow from one to another. The flow will be restricted to one filter and one filter unit at a time, and once the water head drops through the first filter, it will be transferred to another channel and a new filter unit. It can be seen that such a switching program can provide a steady stream of filtered metal to the continuous casting station.

Multi-stage filters can also be used, and the input metal may be very advantageous or even necessary when the quality of the input metal is very poor in terms of non-metallic load. This multi-stage unit can consist of two or more individual filters connected in series. It is also convenient to use a single filter with continuous classification characteristics through its thickness. Of course, in this case, the filter size should gradually become smaller from the initial inlet to the final outlet position.

The filter plate is a disposable item, so the filter plate must be sealed in its proper position in its holder. The device is easy to assemble, disassemble, and clean. It is very preferable to use an elastic sealing gasket to seal the filter plate to its beveled portion. The gasket-type seal ensures leak-free installation and provides an effective separation medium, which is essential for easy disassembly. In addition, because the gasket prevents metal from entering the sealing surface of the bracket unit, their use greatly simplifies the cleaning work and effectively extends the service life of the unit by eliminating the problem of metal corrosion. In addition, due to its elasticity, the gasket can provide enough friction to fix the filter body to the bracket. The sealing device should not wet the specific molten metal, resist chemical attack, and have sufficient fire resistance to withstand high operating temperatures.