Filters of molten aluminum are important for oxidized inclusions, there are two filters to remove the inclusions in molten aluminum.

Filters of Molten Aluminum

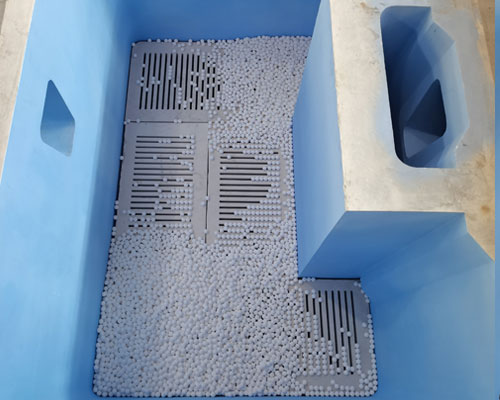

Deep bed filter: The deep-bed filter uses multiple layers of alumina balls with different diameters, arranged inside the refining tank, and from the bottom to the top, there are alumina balls with increasing diameters.

When the molten aluminum flows through the alumina balls from the refining box, as the molten aluminum flows through, the oxide inclusions in the molten aluminum will be blocked by the alumina balls. Because the molten aluminum first flows through the alumina balls with large diameters, it will oxidize The diameter of the aluminum balls is large, and the gap between each other is also large, so the larger oxide inclusions in the molten aluminum are first blocked by the alumina balls. As the molten aluminum flows through the smaller alumina balls, the smaller oxidized inclusions in the molten aluminum are filtered out. After the multilayer alumina ball is filtered, the oxidized inclusions in the molten aluminum are filtered and removed, and the filtering effect is better. it is good. For oxidized inclusions above 20μm, the filtration efficiency of deep-bed filters is above 90%, and for oxidized inclusions above 15μm, the filtration efficiency is above 80%.

The shortcomings are: due to the large volume of molten aluminum in the deep-bed filter, all the molten aluminum in the filter must be drained when changing different alloys, and the alumina balls must be replaced. It takes a long time, and the cost of replacing the alumina ball and the production cost caused by the draining of the aluminum liquid is relatively large. Therefore, this filtering method is only suitable for various alloys, or production processes with less frequent alloy replacement.

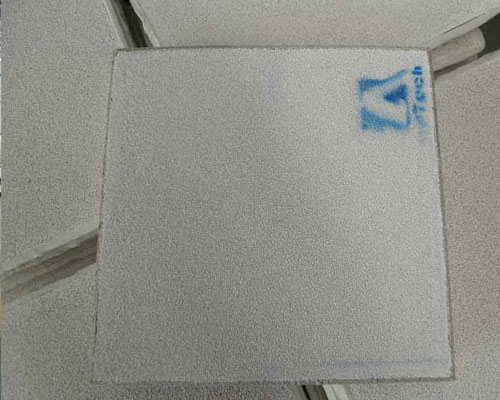

CFF ceramic foam filter is a 2″ thick filter, placed horizontally in the CFF filter box. The filter size is 17″×17”, 20”×20”, 23”×23” and other different sizes to meet different flow rates The required production line.

The filtration of molten aluminum is mainly through the micropores in the ceramic foam filter. When the molten aluminum flows through the micropores, the inclusions in the molten aluminum are subjected to different forces, including the result of the combined action of various forms of motion. Oxidized inclusions are retained in the ceramic filter. After filtering, replace it with a new ceramic foam filter.

According to the oxidized inclusions of different sizes, the diameter and number of micropores of the ceramic filter are different, divided into 20 PPI, 30ppi, 40ppi, 45ppi, 50ppi, 60ppi, 80ppi, 10oppi, etc. The larger the value, the more the number of micropores per unit length, and the smaller the diameter of the micropores, the better the filtering effect. But at the same time, factors such as the size of inclusions in the molten aluminum must be considered. If the size of the inclusions is large, the use of fine-pored ceramic filters will easily block the filter holes and affect the flow of molten aluminum.

Depending on the size of the inclusions, sometimes two ceramic filters with different micropore sizes can be used, such as 40ppi and 60ppi filters, where the aluminum liquid first passes through the 40pi filter, and the larger inclusions in the aluminum liquid are filtered out first, and then the size Smaller inclusions are filtered through a 60ppi filter, so that it can not only ensure the filtering effect, but also prevent larger inclusions from blocking the 60ppi filter.

Using two-stage filtration, 40pi filter and 60ppi filter are used in combination. For oxidized inclusions above 20μm, the filtration efficiency can reach 90%. For oxidized inclusions above 15μm, the filtration efficiency can reach 80%, which is close to the refining effect of deep-bed filters.