Naturally, there is a great need to improve the filtration and degassing of molten metal to remove or minimize such impurities in the final cast product, especially for molten aluminum, especially when the resulting metal is used for aluminum, for example. Decorative products (such as decorative strips) or products with key specifications (such as aircraft forgings and extrusions, and light-weight foil raw materials). The above-mentioned impurities cause performance losses of the final cast product, such as tensile strength and corrosion resistance.

Molten metal, especially molten aluminum in practice, usually contains entrained and dissolved gaseous and solid impurities that are harmful to the final cast product. These impurities may affect the solidification of the final casting metal after melting, which may hinder processing or the ductility of the final product or the processability of the anodizing characteristic is poor. Impurities can come from multiple sources. For example, the impurities may include metal impurities such as alkali metals and alkaline earth metals, as well as dissolved hydrogen and surface oxide films that are blocked and entrained in molten metal. In addition, inclusions may come from insoluble impurities, such as carbides, borides, etc., or corroded furnace and tank refractories.

Strict metal treatment processes (such as gas flux or melt filtration) have minimized the incidence of such defects. However, they have not succeeded in reducing the incidence of such defects to a satisfactory level required for critical applications. Conventional conductive gas flux processes, such as general hearth flux, involve introducing flux gas into a holding furnace containing a certain amount of molten metal. metal. This procedure requires that the furnace be shut down while circulating the flux gas so that the metal being processed remains constant and can be processed. This method has many disadvantages, among them, the efficiency is reduced due to the long-time idling of the furnace during the fluxing, and the efficiency is insufficient due to the low surface area to volume ratio between the gas flux and the molten metal. Further factors include restrictions on the location of the furnace, which allows impurities to re-enter the melt before casting, and high emissions due to the large amount of flux required and its circulation location.

As an alternative to the batch type fluxes described above, certain fluxes are used in series. That is, the operations and related equipment are located outside the melting or holding furnace, and are usually located between the melting furnace and the holding furnace or holding furnace and the casting station. This helps to alleviate the inefficiency caused by the furnace shutdown, but is not as successful in improving operating efficiency, because a large amount of flux gas is often required per unit of molten metal, which is expensive and detrimental to air purity.

Conventionally, melt filtration is used to reduce the extent of the aforementioned defects. The most common form of melt filtration involves the use of molten metal placed in a transfer and pouring tank or a pool of open glass cloth on top of a solidified metal ingot. It has been found that such filters are only partially effective because they only remove larger inclusions. Another filter commonly used is, for example, a bed filter made of tubular alumina. Such filters have many disadvantages, perhaps the most serious of which is the enormous difficulty encountered in controlling and maintaining the pore size necessary for effective filtration. Another difficulty with such filters is that they tend to produce poor initial quality metal at the beginning of each continuous casting run.

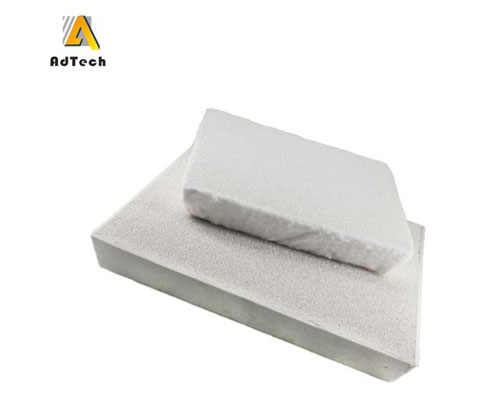

Porous ceramic foam materials are particularly suitable for filtering molten metal for many reasons, including excellent filterability, low cost, ease of use, and ability to be used on a disposable basis. The fact that these ceramic foam filters are convenient and inexpensive to prepare, and can be used once, requires the development of a device for easy and convenient assembly and removal of porous melt filters from the filter unit. We have a matching filter device to install the filter plate.