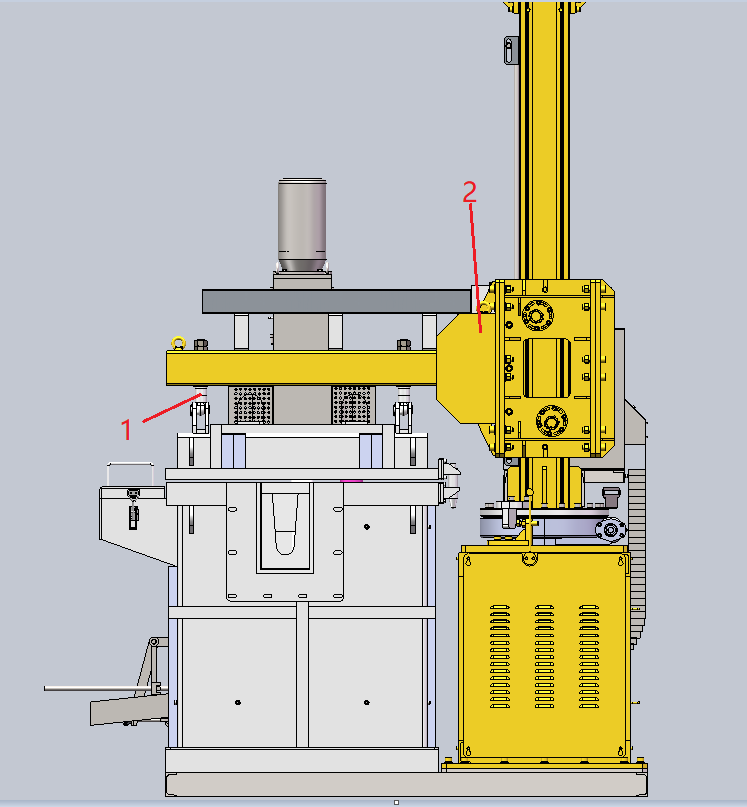

Brief Description: During the lowering process of the degassing machine cover, when the lifting mechanism triggers the proximity sensor at the lowest point, the lowering action of the lid stops, and the response accuracy of the stopping point of the lid is low, which is caused by the following reasons:

1. A hydraulic cylinder drives the lifting of the box cover, and the stroke accuracy of the hydraulic drive is low;

2. The adjustment accuracy of the proximity sensor has a large deviation, which may easily cause the box cover to be completely closed with the box body. However, the sensor signal is not triggered, and the hydraulic cylinder is still operating.

The flatness deviation of the box cover is large, causing a certain point on the box cover to be in contact with the box body, but other parts are not completely closed with the box body.

The above several situations will cause the two hoisting frames of hoisting mechanism 2 to be pushed upwards, causing the hoisting mechanism to generate an upward torque. After a long time, the hoisting mechanism will be fatigued and damaged, which will affect the service life of the roller support and lifting positioning.

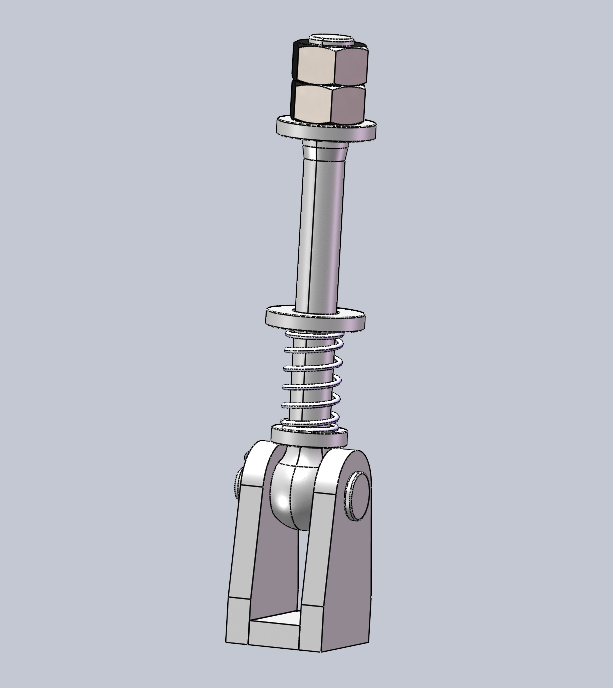

1. Improvement method: The compression spring is used as a buffer between the two gaskets of the hoisting connection component 1, and the compression spring specification: is 3.5*35*65*6.5.

2. On-site application

This improvement method has been applied to the vast degassing equipment in Zhejiang. When the box cover is closed, it can be a flexible buffer, and the field application effect has reached the expected task goal.