Flow control series include Alumina Porcelain Rod, Ceramic Fiber Tube, Ladle Shroud, Aluminum Casting Buoyage, Impurity Separation Ring, Tap Out Cone. They can control the flow of molten aluminum. Flow control series are key accessories in aluminum alloy casting.

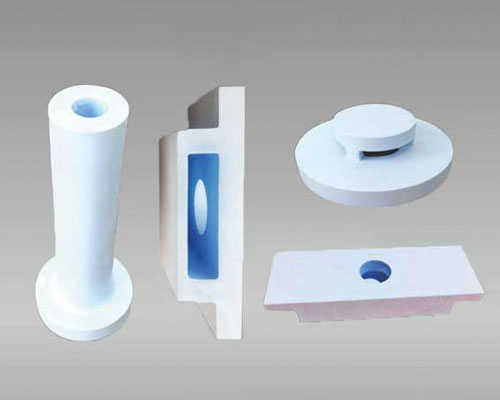

Alumina Porcelain Rod

Alumina porcelain rod and ceramic fiber tube adopt SiO2 molten material. It has strong corrosion resistance and no pollution to metal liquid. You can use them multiple times. The flow control bar and flow tube are suitable for low-pressure casting aluminum wire, aluminum ingot, and aluminum foil. Its function is to remain the parameters stable of aluminum liquid flow and casting.

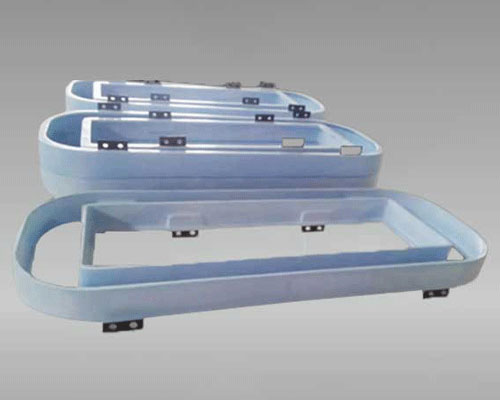

Learn MoreLadle Shroud

Ladle shroud and aluminum casting buoyage adopt SiO2 molten material. The special float plate adopts N17 material. These materials have strong corrosion resistance and no pollution to metal liquid. They have a long service life. Flow pipe and float plate are suitable for low-pressure casting aluminum wire, aluminum ingot, and aluminum foil. They can remain the parameters stable of aluminum liquid flow and casting. The flow pipe and float plate apply to produce high-grade aluminum alloy.

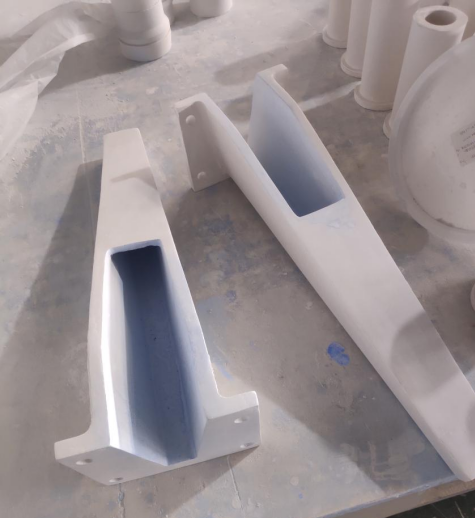

Learn MoreImpurity Separation Ring

The impurity separation ring adopts N17 materials or nanofiber composite material. It has features of low density, high strength, light buoyant, and no pollution to the aluminum liquid. The impurity separation ring is used in the hot-top casting mold. The filtered molten aluminum flow into installed impurity separation ring, which can stop the oxidizing slag flowing into the hot-top casting mold. The impurity separation ring can push off the slag and protect the molten aluminum purity.

Learn MoreRefractory Fiber Cone

A refractory Fiber Cone is made of high alumina fiber. It adopts a vacuum-absorbed shape process. This manufacturing technique has high production efficiency and stable quality. The rate of finished products is up to 99%. It has the advantages of tight blockage, non-stick aluminum, harder than the ordinary cone. It can control or block molten aluminum in a filter bowl or furnace.

Learn MoreThe ceramic nozzle

The ceramic nozzle is the aluminum liquid flow channel used in the processing of electrical poles. The thickness of the material does not exceed 10mm, and the thickness of individual parts is within 5mm. Therefore, the material is easy to crack when it is subjected to the thermal shock of the aluminum liquid. The composite fiber is reinforced by our company The overall ceramic nozzle has good thermal shock resistance and does not stick to aluminum, and the amount of aluminum passing through a single piece can reach more than 300 tons, which has been well-received by customers.

Learn More