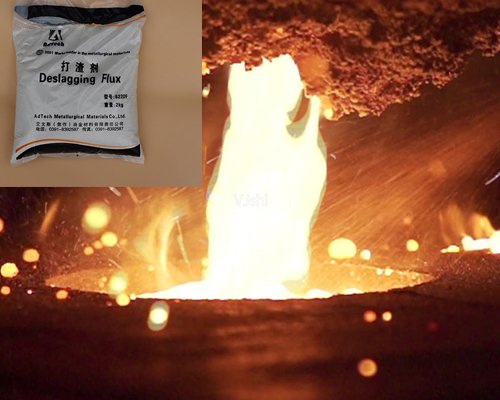

Aluminum refining flux for metal smelting can be used in a variety of aluminum alloy melts, and can be used for metal scrap refining, and slagging. Only need to sprinkle the refining agent on the surface during use, dissolve it in the aluminum liquid quickly and stir it fully.

Adding an appropriate amount of melting aluminum flux when smelting aluminum products can effectively remove the hydrogen and floating oxide slag contained in the aluminum liquid.

The main reason is that the refining agent is easy to decompose at high temperature, especially the generated gas is prone to chemical reaction, and the strong adsorption capacity of inclusions can make hydrogen escape from the melt, so it can have an obvious slag removal effect.

Flux for Metal Smelting is mainly used to remove hydrogen and scum from aluminum and aluminum alloy melts, to make the aluminum liquid purer, and it also has the effect of removing slag.

Refining Agent is easy to decompose at high temperature, and the generated gas can react with hydrogen. The gas and H strongly adsorb the slag and quickly escape from the melt. As the bubbles rise, they are brought to the surface of the molten aluminum to achieve the purpose of refining and purifying, degassing and removing slag.

Romco Metals is a British multinational non-ferrous metal recycler focusing on emerging markets. It currently recycles nearly 3,000 tons of non-ferrous metal scrap, mainly aluminum and copper, each month, and entrusts it to car manufacturers around the world.

The biggest gap in sustainable infrastructure is the lack of a structured circular economy in Africa. Although Africa accounts for one-fifth of the world’s population, its recycling industry is still developing.

If we want to achieve climate goals, we must significantly improve our recycling capabilities. This is the most effective way to reduce greenhouse gas emissions. It makes sense to take full advantage of the large number of key metals found in dusty drawers, garages and landfills.