The foam ceramic filter board adopts a three-dimensional network structure, which is superior to the previous honeycomb foam type. Ceramic foam filter has high open porosity, low filtration resistance, small normal static difference, high surface energy, strong adsorption of impurities, and superior thermal shock resistance, high strength, no slag and other advantages.

Foam ceramic filter board is widely used in the aluminum melt filtration and purification in the aluminum processing industry with their excellent performance, to better improve the quality of aluminum materials, and expand the application in the fields of environmental protection engineering, heat energy utilization, and catalytic carriers.

Filtration and Purification Mechanism of Foam Ceramic Materials

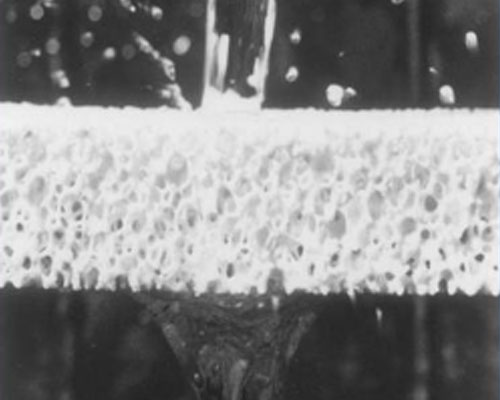

1. Through mechanical filtration such as screening inertial impact interception, diffusion interception, friction, sedimentation, etc., the filtration efficiency is proportional to the mesh aperture of the foam ceramic. The smaller the mesh, the stronger the interception ability for small particles.

2. Sediment layer or filter cake layer effect. With the deposition of particles in the melt and the interconnected and uneven grid support walls, the ability to capture miscellaneous particles is improved.

3. The rough surface formed due to the gaps on the surface of the mesh frame increases the interface between the molten aluminum stream and the ceramic solid surface, which can promote the flow of particles in the molten aluminum stream to be more disordered, which is conducive to the capture and deposition of solid particles.

4. Due to the microscopic cracks and pinholes on the surface of the mesh frame body, fluoride with strong affinity for Al2O3 particles is pre-deposited, which promotes a complete filter cake effect and strong chemical adsorption, and the ability to capture the remaining impurity particles is more strong.

5. Furthermore, from the temperature field effect of the melting process and the transmission process of the metal melt structure, the concentration difference of the alloy solute is bound to be formed. The metal melt is redistributed—integrated—redistributed—integrated again. It is also a very good alloying treatment process. Some high melting point metal phases and compounds re-aggregate and grow, and the fine impurities will accumulate and grow, which is beneficial to filtration and capture. This can also be explained by the changes in the concentration of H, Al2O3, Fe phase, and Ti phase before and after filtration. Especially two-stage filtration or pore gradient thick plate filtration is more obvious. Therefore, under the same prerequisites, the new ceramic foam filter plate has a high removal rate of the aluminum melt impurities, the static pressure difference before and after filtration changes more with time, and the H content in the aluminum melt before and after filtration also changes significantly. Of course, the smaller the holes of the ceramic foam are selected, the more clean the aluminum melt can be improved.