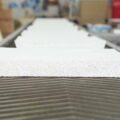

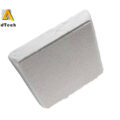

Foam Ceramic Filter Manufacturing Process uses automatic extrusion equipment to make the slurry evenly distributed in the foam skeleton. With the development of science and technology, the requirements for aluminum and its alloy materials are getting higher and higher, and the traditional refining and degassing process cannot remove the tiny non-metallic inclusions in the aluminum melt. Therefore, many people have studied the purification methods, which can be divided into adsorption purification, physical purification and filtration purification according to the different mechanisms and forms. Filtration purification is to make liquid metal flow through a medium, which captures impurities by a certain mechanism to purify the metal. Foam ceramic filters, filters used to improve the productivity of cast aluminum, are widely used in the production of semi-continuous casting and die castings.

Foam Ceramic Filter Manufacturing Process

The main raw material of the porous filter material is high-temperature alumina. It does not react with molten aluminum, does not dehydrate during the roasting process, has a very small shrinkage, and has relatively stable physical and chemical properties.

The slurry used is mainly composed of various components of water suspension colloid. When making embryos, the slurry can firmly adhere to the foamed plastic screen. When grouting the grout, do not be too thick or too thin. Too thick, the mud will not easily fill the foam on the sieve. If it is too thin, it is easy to settle on the plastic net and form uneven slurry.

Therefore, controlling proper moisture is the key to pulping. In addition, the adhesiveness of the slurry should be moderate. Tests have found that adding too much low-temperature binder will result in too much agglomeration of the slurry. Extruding the excess slurry will make it difficult to restore the foamed plastic mesh. Adding too little binder will result in too little bonding performance of the slurry, and the slurry will not be able to adhere tightly to the foamed plastic net. After demolding, it will have no strength and will easily disassemble. Hang up even if it has a certain strength, because the slurry is too thin, the network structure is very brittle, and the overall strength is poor.

The metal mesh is used to make the oven board, which is used as the supporting board for the foam block drying body after the slurry is placed. It is first dried at room temperature and then dried in hot air. Firing is a key step in the process of porcelain making. Mastering the firing changes during the high-temperature firing process and formulating the correct system are the keys to firing high-quality products.