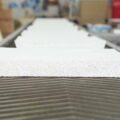

Foam ceramic filters manufacturer AdTech can provide 20-80 PPI ceramic foam filter. The ceramic foam filter is made of continuous mesh foam plastics, immersed in mud and baked at high temperature. Therefore, raw materials used for making filter plates are divided into foam and mud.

The foam used for producing metal foam filters should have sufficient elasticity and strength to ensure recovery and breakage resistance when immersed in mud. In the submergence phase, there are no congenital defects, such as local depressions and cracks. The parameter that usually describes the foam specification is PPI (the number of holes per inch), which is the number of holes per inch.

The mechanical properties and surface quality of ceramic filter plates are directly related to the mud. General requirements for preparing ceramic foam filter mud are:

It should have proper viscosity. If the viscosity is too low, the foam will not absorb enough mud, which will reduce the strength and specific gravity of the filter plate. Although the viscosity is too high, it can increase the strength, but it will cause too many dead holes and even produce slag on the surface.

Mud must be fluid to ensure that mud can be easily squeezed into and extruded when foam is immersed.

The main raw materials of the slurry should have a certain degree of hydrophilicity to ensure that the slurry forms a uniform suspension of glue. If the hydrophilicity is poor, the solid in the mud will easily precipitate and remain in the foam during the immersion process, resulting in the increase of the dead hole and filter plate brittleness.

Good mud has a smooth, delicate and even handle, and will not cause precipitation after long-term storage. The composition of the mud and the specification of the raw material have a decisive influence on the performance of the mud. Even if the specifications of the same raw material are slightly different, the deformation resistance, compressive strength and surface brittleness of the final product will be greatly different.

AdTech is a professional foam ceramic filters manufacturer. Ceramic foam filter is filtrating by adsorption principle. It can effectively remove large inclusions in aluminum liquid and effectively adsorb small size inclusions. It is not effective to reduce the pollution of aluminum slag. Good thermal shock resistance and improved corrosion resistance to molten metal. Automatic production line, accurate size, more suitable for CFF filter box.