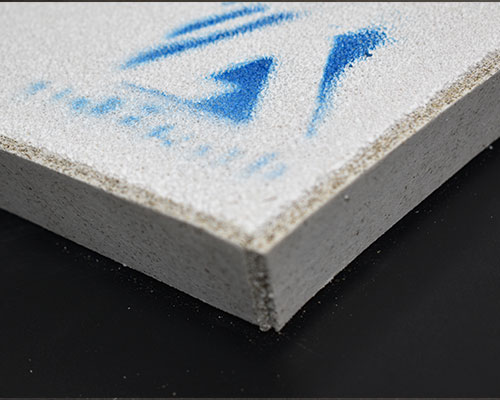

AdTech ceramic foam filter for foundry adopts three different specifications of sealing gasket: fiber paper edge; fiber cotton edge, expanded cotton edges.

The ceramic foam filter for foundry is surrounded by a sealing liner, which acts on the contact surface of the filter box, so as to prevent the aluminum liquid from leaking through the contact surface. The ceramic filter for casting adopts the adsorption principle to filter, which can effectively remove the large inclusions in the aluminum liquid and effectively adsorb the micron-sized inclusions. The same number of specifications have high filtration accuracy. The ceramic foam filter for foundry can also be customized according to the shape and size of the customer’s needs.

In casting production, the casting rejection rate due to casting defects such as non-metallic inclusions is generally as high as 50% to 60% of the total number of rejects. Inclusion defects not only seriously reduce the mechanical properties of the casting, but also have a harmful effect on its processing performance and appearance.

Purifying the liquid casting alloy and reducing or eliminating various non-metallic inclusions is undoubtedly a very important technical measure to obtain high-quality castings. CFF Filtering technology can effectively achieve the purpose of purifying liquid casting alloys.

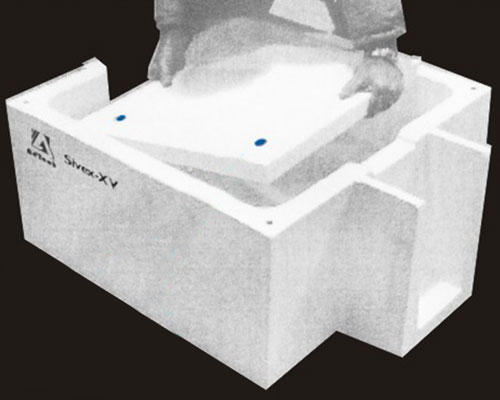

Online plate-type CFF filtering unit adopts advanced high silicon melting technology. It is used for the filtering and purifying of the molten aluminum, matching with the ceramic foam filter. It can filter the inclusions and tiny particles in the molten aluminum. Mainly used for molten aluminum purification with high value-added and high technical performance. To replace the high-cost ceramic tubular filtering unit and ordinary plate-type filtering unit. The micron-level impurities in molten aluminum can be removed by this unit with our related technical guidance. Such as the casting for aluminum alloy in rail transit, micron foil, PS plate in the printing industry.