In order to obtain a high-quality product, it is necessary to remove the inclusions. Liquid metal filtration through ceramic media is an effective way to clean metal. Foundries can use different types of ceramic media online, such as foam ceramic filters, porous tube filters, bonded ceramic filters, and deep bed filters.

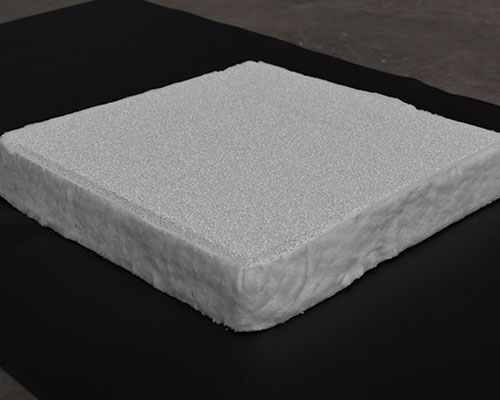

The use of ceramic foam filtration to remove inclusions in the foundry industry is well known. Alumina ceramic foam filter is a commonly used filter tool in the aluminum and non-ferrous alloy smelting industry. The alumina ceramic foam filter is white and made of high-purity alumina (Al2O3). This filter provides deep bed filtration to remove a large number of impurities from the aluminum melt, and works at temperatures as high as 1100°C. It has excellent resistance to high thermal shock, while maintaining effective removal of impurities through continuous and thorough filtration.

The ideal filtration performance of our Foundries Foam Ceramic Filters depends on the 3D structure of the ceramic matrix. In addition, they are characterized by very good thermal conductivity, both stability, and resistance to sudden temperature changes.

We provide ceramic foam filter models ranging from 20 to 60 PPI, and the filter plate size is 7in to 26in. They are extremely effective tools for obtaining molten metal purity during the casting process.

The mesh shape of the foam filter provides thorough and deep filtration to remove impurities from the molten metal stream. The ceramic foam filter has excellent resistance to high thermal shock, while maintaining high-efficiency filtration.

The ceramic foam filter has a gasket on the edge to help secure the filter in the filter box and ensure that no metal bypasses the filter. There are different types of gaskets, fiber gaskets, and expandable gaskets. You can also choose an alumina ceramic foam filter without the gasket.

Ceramic foam filters have excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner.