High Grade Ceramic Foam Filters have been used for many years, it can improve the quality of castings and obtain high-quality aluminum die casting parts. The main function of the filter is to enable many users to remove foreign materials from the molten metal. In Europe, most ceramic foam filters are used to reduce inclusions in liquid aluminum alloys. These high-grade ceramic foam filters for casting are lightweight, high strength, and large pore size. Coarse filters have fewer pores per inch, have a higher possible flow rate, and have longer resistance to blindness.

Filter cake filtration is the most familiar mechanism in which the filter acts as a sieve and retains particles larger than the pore size of the filter surface. These retained particles form a sieve and trap particles smaller than the filter pore size. As the filter cake accumulates on the filter surface. Once this cake begins to form, the original filter is only used as a support for the filter cake. And the actual filtration and melting of the filter cake achieve. With the accumulation of filter cake, the pressure drop of the entire filter will increase, and the flow rate will decrease or stop sharply. At this stage, the filter is called a blind hole or plug.

High Grade Ceramic Foam Filters Supplier

AdTech provides high grade ceramic foam filters that can effectively improve the mechanical properties of cast materials. Reducing the number of these inclusions by using a filter reduces the number of parts that can nucleate these cracks, thus improving the mechanical properties of both cast metals and reducing the spread of these properties. AdTech ceramic foam filters have substantial strength at ambient and molten aluminum temperatures, are durable, have high thermal conductivity, and are resistant to chemical attack. They are useful in aluminum gravity casting, pressure die casting, low-pressure, and high-performance sand foundries to remove inclusions.

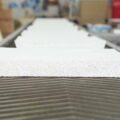

Manufacture of aluminium alloys meets the requirements for higher purity of the cast metal in order to increase quality of the manufactured intermediate for the final production (foils, blocks, ingots, rods, sections). The filtration thus contributes by the lower reject rate of manufacture of the final product and by its higher quality.

Metal casting by continuous or discontinuous campaigns needs some hundreds of tons molten aluminum, and therefore the large-area filters are used for filtration. They are placed in the liquid metal distribution system. We recommend to place the filters seated in the ceramic filtration boxes utilizing horizontal filter layout. Prior to casting itself, the filter has to be preheated adequately to secure its correct functioning.