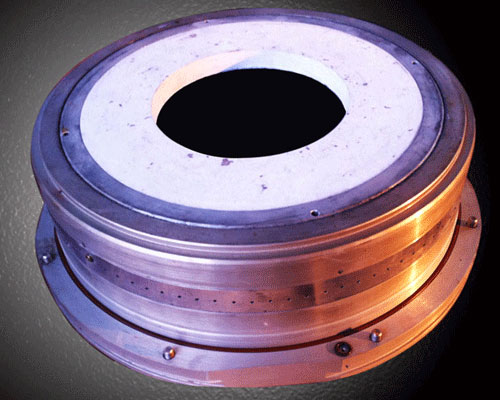

High purity graphite ring adopts high-purity graphite material, and is made by precision CMC equipment. It is the best choice for hot top casting, can meet the production of high value-added, high technical performance requirements.

Graphite Ring Specification

| 3in | 3.5in | 4.5in | 5in | 5.5in | 6in | 6.5in | 7in |

| 8in | 9in | 10in | 12in | 14in | 16in | 18in | 20in |

Technical Parameter

| Item | Density (g/cm3) |

Compression Strength (Mpa) |

Thermal Expansivity (X*10-6/℃) |

Max Working Temperature (℃) |

| Index | 1.4-1.5 | 15-16 | 4-4.5 | >1000 |

Advantages

- High-purity graphite ring has a smooth glazed surface, high geometric processing accuracy and low maintenance cost.

- No delamination and peeling phenomenon. It can effectively reduce the pollution of aluminum liquid, and achieve pollution-free precision aluminum casting.

- Erosion resistance, good thermal shock resistance, strong corrosion-resistance to molten metal.

- The life is long for normal 800-1200 casting times, graphite ring can achieve energy saving and consumption reduction.