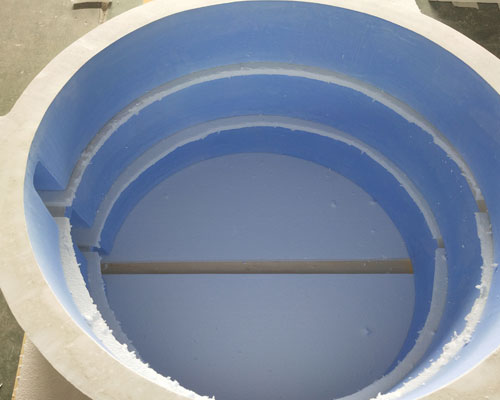

The molds of the new hot top casting accessories are densely arranged on the integral water tank, and a draft tube is arranged above the mold, and some have an adapter plate between the mold and the draft tube, and the draft tube is sleeved on it Inside the shunt plate.

Practice has proved that in the production of ingots with smaller diameters, the new hot top casting process equipment presents the following advantages:

- Multiple ingots can be cast at one time. The number of ingots that can be cast per casting is determined by the area of the casting well and the diameter of the ingot. An aluminum processing plant can cast small-sized ingots at one time, which is far more productive than ordinary molds and horizontal casting.

- The casting operation is simple. At the beginning of casting, open the casting orifice. When the molten aluminum in the launder is 90% high, pull up the baffle in the manifold at the same time, and quickly rake the molten aluminum into the guide pipes. After the start of casting, adjust the water pressure, water volume and increase the liquid level in the launder in time. In this way, dozens of ingots are cast at a time, and only skilled casting workers are required during the entire casting process.

- Easy troubleshooting. In the casting process, if a certain ingot is found to be cracked or leaked, it is only necessary to plug the draft tube with a plug.

- The surface quality of the ingot is good. Practice has shown that the pre-casting preparations are done, especially for the molds. If the molds are lubricated, a better ingot surface can be obtained.

AdTech offers hot top casting accessories for aluminum casting, includes Ceramic Launder, Ceramic Sprue Bush, Distributing Launder, Alumina Ceramic Ring, Hot Top Casting Cap, High Purity Graphite Ring. They have high corrosion resistance, high geometry precision, smooth surface, long service life, low maintenance cost, and non-pollution to molten aluminum, especially suitable for Wagstaff equipment. The molten aluminum is poured into the mold crystallizer from the distribution plate during casting. They can meet the technical requirements of precision casting of aluminum alloy.