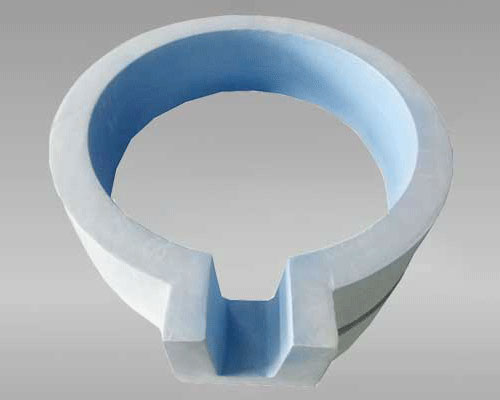

Hot top casting cap is also called casting funnel. AdTech Casting Funnel uses high silicon melting 140 materials. It is the best choice for hot-top aluminum casting. It has high corrosion resistance, high geometric precision, smooth surface, long service life, low maintenance cost and non-pollution to molten aluminum. AdTech hot top casting cap can meet the high value-added, high-tech performance aluminum casting requirement.

Specification

| 3in | 3.5in | 4.5in | 5in | 5.5in | 6in | 6.5in | 7in |

| 8in | 9in | 10in | 12in | 14in | 16in | 18in | 20in |

Technical parameter

| Item | Density (g/cm3) |

Compression Strength (Mpa) |

Thermal Expansivity (X*10-6/℃) |

Max Working Temperature (℃) |

| Index | 1.4-1.5 | 15-16 | 4-4.5 | >1000 |

Casting Funnel Features

- Hot top casting cap has high hardness, high erosion resistance, high geometric precision, low maintenance cost, smooth surface.

- Non-peeling off, non-pollution to molten aluminum, and it obviously improves the quality of aluminum alloy.

- Good thermal shock resistance, reduce the pollution to molten aluminum for corrosion resistance casting.

- Itis excellent to use with BN, which can save

Instructions of Hot-top Casting

- Choose the right size hot top casting parts, and install them.

- Install the distribution plate, thimble, transition plate, distribution launder and graphite ring above the platform, and thimble, transition plate, graphite ring below. Ensure the product smooth, clean, undamaged and seamless. It is better to seal around the side and bottom with ceramic fiber blanket or ceramic fiber paper for thermal insulation.

- Preheat the hot top casting platform uniformly to 260℃-350℃. If electric heating is not available, heat it by flame is recommended to get rid of adsorbed crystal water. Direct fire on the lining body is prohibited.