The filtration efficiency of the molten aluminum filter closely relates to its correct installation and use. At the same time, it is also necessary to prevent the recontamination phenomenon of the clean liquid aluminum after filtration.

How to Use the Molten Aluminum Filter

In general, the use of alumina foam ceramic filters should pay attention to the following aspects.

1. Correct Selection

Select the correct ceramic filter size and hole number specifications. You must take into account factors, such as the flow rate range of a particular casting type, the maximum liquid level of the metal during filtration, the total filtration volume, and the cleanliness of the original liquid aluminum.

2. Pretreatment

The pretreatment includes the dross slagging and cleaning of the aluminum melting furnace and the holding furnace. Especially the online degassing unit is still necessary, because it can not only reduce the hydrogen content of the melt, but also remove some non-metallic inclusions.

3. Compatible With the Refractory Filter Box

The adaptation of the two facilitates sealing, which not only prevents metal from flowing into the casting box from the gap, but also prevents the foam filter from being too light and floating in melton aluminum to fail.

4. Pre-heating Before Use

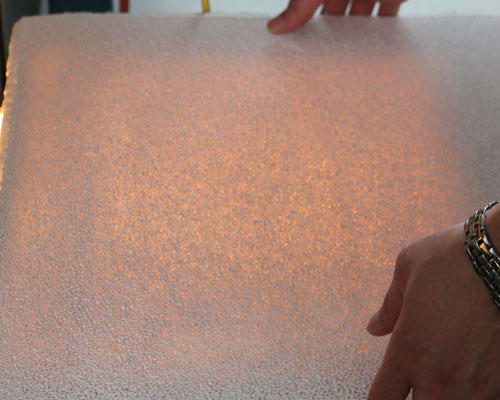

Preheating of molten aluminum filter can remove moisture and facilitate initial filtration. Preheating can adopt electric or gas heating. Under normal circumstances, it takes about 15 minutes.

5. Ceramic Filter Filtration Process

In the normal filtration process, there is no need to carry out slagging, so as to avoid knocking and vibration of the filter plate. At the same time, the launder should be full of liquid aluminum.

6. Clean Up the Filter Box

After casting, clean up the filter box and remove the filter plate after solidification.

Ceramic Foam Filter Manufacturer

Since 2012, AdTech company has been focusing on the research and development of highly absorbent alumina ceramic foam filters. Now, the technology of ceramic filter has been mature, and it is widely accepted in the market. It can effectively remove the inclusions in the aluminum liquid, and absorb the micro-sized fine inclusion particles. Ceramic filter plates play an important role in the aluminum alloy casting industry. If you are interested in our products, please feel free to contact us.