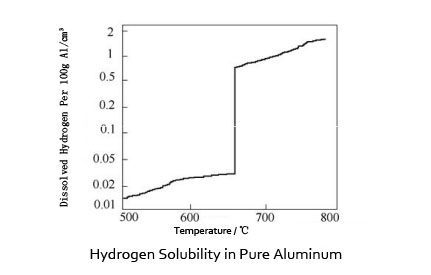

In the process of heating and smelting, solid and liquid aluminum have a certain ability to absorb H₂, 0₂, and other gases. This property of aluminum is called gettering, and it is one of the important melting characteristics of metals. Practice has proved that the gas present in aluminum will adversely affect the performance of aluminum and alloys and the quality of cast and rolled strip. The Hydrogen Solubility in Pure Aluminum is the main reason for the blowholes and air passages of the cast strip, and even the material is hydrogen embrittled. The inclusion of oxygen and nitrogen and their compounds in the material will deteriorate the process and mechanical properties of the material.

Therefore, another main task of smelting is to remove the gas dissolved in the metal melt. Studying the source of the gas, the dissolution process of the gas in the metal, the factors affecting the gas content of the aluminum liquid, the degassing principles and methods, and aluminum refining are the keys to make the molten aluminum degassing process.

Hydrogen Solubility in Pure Aluminum

In the atmosphere, the partial pressure of hydrogen is extremely small. Therefore, it can be considered that, in addition to the metal raw material itself containing gas, the gas in the metal melt mainly originates from furnace gas, refractory materials, moisture brought into contact with the melt, hydrocarbons.

Aluminum is one of the most susceptible alloys to contamination by gases and inclusions. This is mainly determined by its own characteristics. Hydrogen is the only gas that dissolves in large quantities in the aluminum melt. The solubility of hydrogen in the liquid and solid phases of aluminum per gram of aluminum is 0.65 cm³ and 0.034 cm³, respectively, with a difference of about 19.1 times. The normal hydrogen content in aluminum per gram of liquid is 0.10~0.40cm.

AdTech offers degassing unit for molten aluminum, which can remove the hydrogen, gas, and other residues from the aluminum liquid. The inner lining is made of high-silicon molten material. It has a long service life. The non-stick aluminum effect is good, with no pollution to molten aluminum. The spoiler of the inner lining can prevent air and oxides from entering into the liquid aluminum.