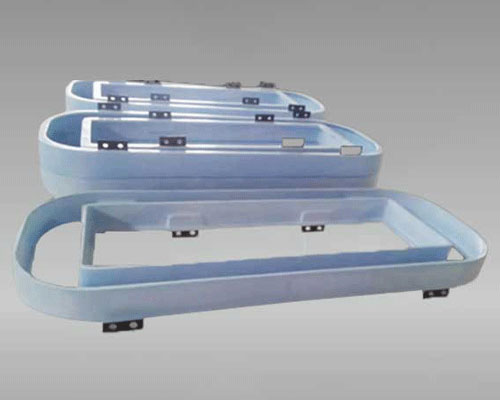

Impurity separation ring is made of N17 material. Slag ring can intercept slag in the molten aluminum. It has low density, relatively high strength, and high light buoyancy. The slag retaining ring has a smooth surface, no pollution to liquid aluminum. It is resistant to scouring and can be used multiple times. The slag separator can meet the aluminum alloy precision casting products. The slag dart ring for aluminum alloy casting includes a slag ring body and a hanging piece installed on the skim ring body. When aluminum alloy casting is required, the skim ring body is placed under the filter bag, and the hook is fixed to the outside to prevent the slag ring body from moving with the aluminum liquid.

Specification

| items | Dimensions | Special dimensions | Package | Special package |

| Flow pipe | 100-2600mm | As drawing | 10pieces/box | As required |

Applications of Slag Retaining Ring

The slag retaining ring is used in conjunction with a casting crystallizer. By setting a slag retaining ring, the molten aluminum first enters the annular range. Oxidation slag and other slags may enter into the crystallizer. The slag ring body can intercept the slag and prevent it from flowing into the inside. The impurity separation ring reduces the risk of slag contamination.

Instructions

1. Assemble the impurity separation ring with metal buckle matching with a hot-top casting mold.

2. Test the buoyancy according to the amount of molten aluminum and the size of the hot-top casting mold. Adjust the counterweight sheet between metal buckle in the rings, so as to comply with stable casting.

3. Make sure proper assembling, and then start casting.

By setting the impurity separation ring, the aluminum liquid filtered through the filter bag first enters the annular range formed by the slag ring body. The slag such as oxidized slag may be brought into the crystallizer. The slag ring body can intercept the slag such as oxidized slag. Let it flow out of the slag ring, and control scum like oxidation in the slag ring, thereby reducing the risk of aluminum alloy ingots being contaminated by slag. Therefore, AdTech’s slag ring can improve the quality of aluminum alloy ingots.

In order to prolong the service life of the impurity separation ring, it is preferable that the slag retaining ring is made of non-stick aluminum material and does not react with the aluminum liquid. Specifically, the surface of the slag retaining ring is provided with a boron nitride coating, which has high-temperature resistance, The advantages of corrosion resistance. Further, in order to better adapt to the crystallizer, the slag retaining ring is a rectangular ring, and the arc transition at the corner of the rectangular ring.