Launder for Aluminium Casting will be connecting the customer’s existing gas fired aluminum melting furnace to three (3) new electric resistance aluminum holding furnaces located at their three diecast machines.

The casting launder eliminates equipment and manpower costs, as well as the inherent dangers, associated with transferring molten aluminum from the melting furnace to the three holding furnaces with fork lifts and transfer ladles. The launder also keeps the molten aluminum at a set point temperature until it reaches the holding furnaces which means there is no temperature lost during transfer.

Overall, this metal transfer system saves energy by eliminating two pours. One from the melting furnace to the transfer ladle and another from the transfer ladle to the holding furnace. It eliminates the oxides and the resulting hard spots that form each time the molten aluminum is disturbed making it very efficient for the customer.

Launder for Aluminium Casting

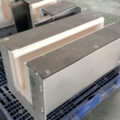

Launder Segments For Aluminium Casting including:

•Air cylinder operated launder and holding furnace heating lids for ease of access for cleaning and maintenance.

•Highly insulated calcium silicate board linings that are naturally non-wetting to aluminum saves energy and makes cleaning a breeze.

•A working tap encased in a bolt-on end cap on the launder allows for tapping metal for remote holding furnaces not attached to the new launder system.