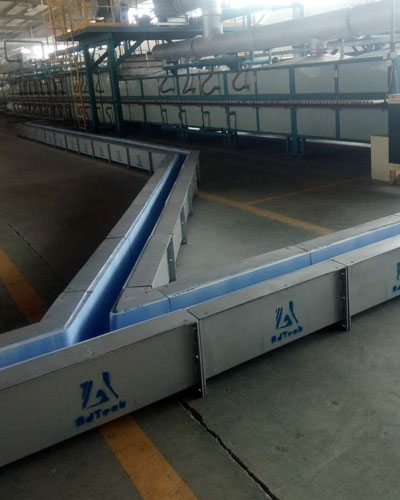

AdTech supplies a launder for the conveyance of molten metal. The metal flows in the lower part of the launder construction in a channel defined by a refractory mass, the launder being heat-insulated so that, in operating conditions, the metal forms a solid zone in the porous refractory mass.

The essential features of the launder construction include a cover part that is provided with electrical resistors, ensuring that the metal remains melted and the launder sufficiently hot throughout the process, and a gas burner that prevents the metal from cooling under the effect of the gas flowing in the launder channel.

The manufacture of aluminum includes a stage in which aluminum anodes are cast from crude aluminum in a casting facility to electrolytically clean the aluminum. Aluminum is drawn from the smelting furnace through the molten pool and trough and fed into the casting machine.

The launders equipped with steel sleeves are lined with refractory materials. They are open-type launders or launders with a cover. Install the launder with an appropriate inclination to influence the flow of the melt by gravity. In order to transfer and meter the melt, a launder such as a stabilization launder is also required, in which the melt is poured from the melting furnace into the stabilization launder, and the molten metal is stabilized in it before being guided to the launder.

When increasing the capacity of the casting equipment, the melt launder must be made longer, resulting in greater cooling and solidification of aluminum in the launder than before. When aluminum solidifies in the launder, the molten flow of the melt is blocked, and the molten metal flows through the launder.

In order to prevent solidification, the molten aluminum is heated in the melting reactor to a sufficiently high temperature to keep the temperature of the molten metal in motion and the launder is heated to the casting machine.

The launder is lined with refractory materials, and its wear is proportional to the temperature of the transported metal: the higher the melt temperature, the faster the launder liner wears. Naturally, this brings additional maintenance costs. When the runner is still cold, the solidification of the melt during the casting process is particularly easy to proceed in the initial stage of casting.

At the end of casting, the trough and launder are rapidly cooled, thereby solidifying the molten metal in them. Similarly, in connection with any process disturbances, the flow of molten metal in the launders and launders may be interrupted or reduced to a certain degree to allow the metal to solidify and the entire launder system should be repaired before continuing casting or starting a new casting.