Our refractory technologies may allow producers to avoid the need to “super-heat” the metal in in-line equipment, and most importantly, reduce holding furnace temperatures. AdTech Launders are extremely abrasion-resistant. Due to the superior thermal shock resistance of launders for aluminum melting furnace, AdTech is far outlasting standard fused silica materials in casting launders applications.

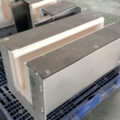

Launders for Aluminum Melting Furnace

The top metal casting companies in the world demand the best. That’s why they choose Adtech, the leading refractory, for use in their launders and other metal delivery systems.

Because of its thermal insulating properties and durability, Adtech is the only refractory material specified by Wagstaff for their billet casting systems and low-warpage ingot casting launders. AdTech High-Performance Metal Transfer System utilizing Adtech refractory technologies allow producers to eliminate launder pre-heating.

When your process calls for superior wear and durability, Adtech preformed fused silica shapes are the ones to choose from. Launders For Aluminum Melting Furnace shapes are precision cast into a wide variety of sizes and shapes, from small and intricate to extremely large – even shapes with complex internal features, typically without the need for costly machining.

Adtech preformed shapes provide superior wear resistance in your most critical high flow/high-velocity applications. In addition, its excellent thermal shock resistance. and thermal insulation make ideal for molten metal handling.