The purpose of liquid aluminum refining is to remove slag and gas. The refining agent produces a number of compounds or gases through a certain chemical reaction with the molten aluminum, which plays the role of degassing and slagging. The main components of the refining agent are CL-, K +, Na +, A LF3-, CO3-and so on. There are scouring agents that focus on degassing and scouring agents that focus on slag removal. Generally, it is a common type slag removing and degassing refining agent. When the temperature of the molten aluminum reaches 720 -730 ℃, the refining agent and the slag remover are uniformly blown into the molten aluminum at various parts with high-purity nitrogen (nitrogen content of 99.99%) through the refining device to suspend the aluminum The slag in the liquid floats to the surface of the molten aluminum for extraction. In order to enhance the liquid aluminum refining degassing effect, sieved hexachloroethane is added in the refining and kept for 5-8 minutes. When using the refining agent, you must pay attention to it, and never let the wet refining agent enter the aluminum liquid.

Most of the smelting tools are ironware, such as crucibles, iron rakes, bell jars, ladles, sampling spoons, etc. If these ironware are not treated and preheated, the iron content in the molten aluminum will be increased, and at the same time, the gas and inclusions in the molten aluminum will be increased due to the corrosion of the molten aluminum due to the absorption of water vapor. Therefore, the smelting tools must be degreasing, rust removed and painted before use (see Table 1 for the coating formula). Painted tools must be thoroughly dried.

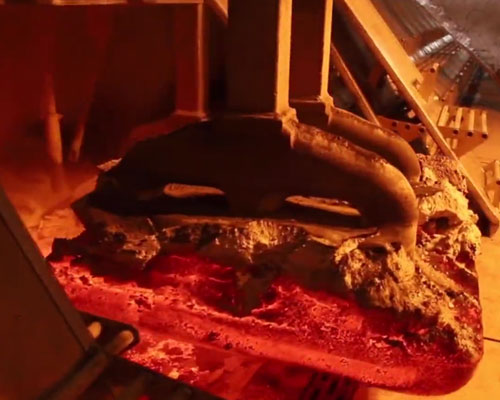

The melting and casting furnace has been used for a long time. The accumulation of slag on the furnace wall and furnace bottom will affect the absorption of metal additives and the degassing and slag removal work, and it is easy to produce defects such as unqualified alloy composition, loose ingots and slag inclusion, so every week you can use cleaning agent or manual cleaning once every 10 furnaces.