Liquid metal filters are located inside the CFF Casthouse between the aluminum melting furnace and the online degassing unit. It is used to remove the inclusions generated between the refining system and the mold table. During the metal solidification process, the liquid metal filtration ability of the ceramic foam filter to capture these inclusions is essential to keep the ingot clean. This ensures the quality and productivity of downstream processes such as forging, extrusion and rolling.

In conventional continuous casting operations, aluminum or its alloys are melted in a furnace and transferred to the pouring tundish of the continuous casting machine through other containers. Entrained in the molten aluminum are oxides of other metals in the form of impurities, non-metal oxides, and other solid contaminants. In addition, gaseous products, especially hydrogen generated by the reaction of molten aluminum and moisture in the various containers of the system and in the surrounding environment, are usually trapped or dissolved in the molten aluminum. If not removed from the molten metal before casting, both particulate matter and gaseous products can cause undesirable voids and inclusions in the cast metal. When the cast metal is subsequently processed to produce the final product (such as continuously formed bars and wires), inclusions and voids often cause defects, which can lead to fractures and cracks in the processed product, poor mechanical properties, and reduced electrical conductivity of the casting.

Prior art proposals to overcome the above-mentioned difficulties include many methods and equipment for removing gaseous hydrogen from molten metal by passing flux gas. Many filtration systems and methods have also been proposed for removing solid particulate impurities from molten aluminum before introducing metal into the mold. Many known prior art flux and filtration systems use a filter medium that includes a loose bed of refractory particles, such as alumina balls, through which molten aluminum passes countercurrent to the flux gas.

However, with the prior art granular filter media, it is not easy to control the size of the particles to be filtered, and the filter bed often suffers from channel problems, which leads to loss of filtration efficiency and frequent clogging. Of course, a clogged filter bed needs to be shut down to remove and replace the filter bed, or at least the casting operation needs to be interrupted to clean the filter bed on site.

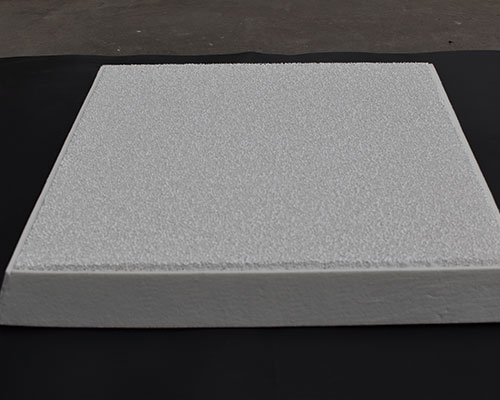

When using a ceramic foam filter, gently lay the filter in the filter housing, press the sealing gasket around the filter by hand to prevent molten aluminum from dispersing or floating away. Use electric or gas burning to preheat filter housing and liquid metal filters evenly for 15-30 minutes, make sure their temperature close to molten aluminum.