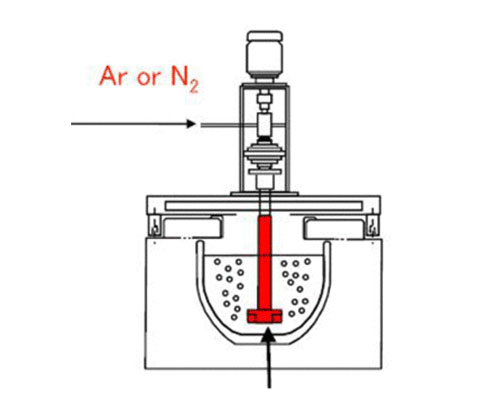

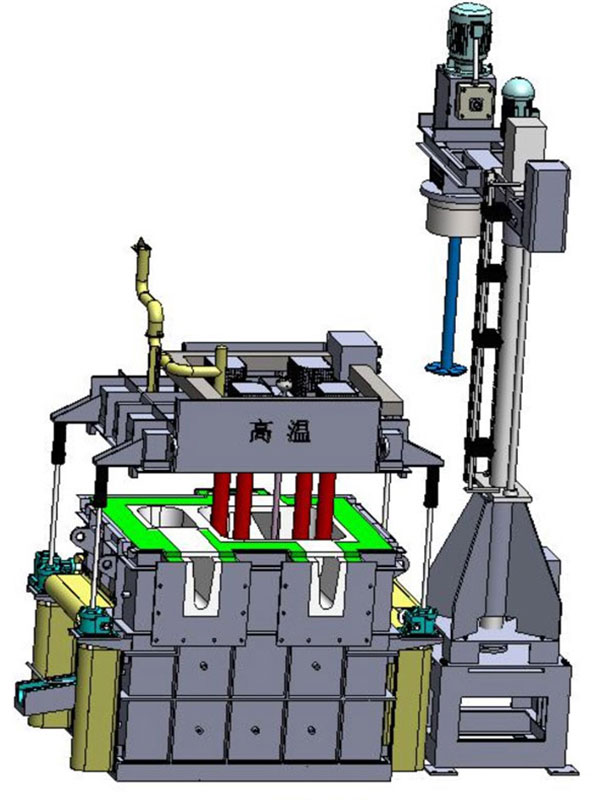

The main components of the aluminum degassing unit

The main components of the degassing unit include the processing box, the lifting device, and the heating system.

Processing Box

The processing box of the Degassing Unit includes two inner chambers, a purification chamber, and a heating and insulation chamber.

The middle is separated by a SiC partition. The bottom of the two chambers communicates. After the aluminum alloy liquid is degassed and slag-removed in the purification chamber, it flows into the insulation chamber from below the partition. It is placed under heat preservation, and the heat preservation chamber is heated by using a U-shaped silicon carbon holding jacket and a silicon carbide protection tube immersed in an aluminum alloy liquid. The outer shell of the box is made of a 10 mm steel plate, and the inner lining is made of refractory material.

The conjoined front and rear of the treatment box are independent internal cavities. It is convenient for the heater to conduct directly and carry the submerged flow of the processed aluminum alloy liquid.

At the suggestion of our company, there are slag removal doors on the lower part of the two side walls of the box.

The slag removal in the cavity can be completed without activating the cover, which prolongs the service life of the inner cavity of the box, and its heat insulation performance is also improved, and heat loss is increased. The reduction and thermal compensation of the heater can completely meet the temperature requirements of the production process.

The box has a good seal, which can prevent air from entering the box and secondary pollution of the aluminum alloy liquid. Equipped with a hydraulic tipping device, it can be completely discharged after the casting work is completed or the alloy is replaced, and the box can be completely emptied. The heater does not have to be energized for a long time to keep the heat, which can relatively reduce power consumption.

Lifting System

In order to ensure its accurate positioning, two hydraulic cylinders of the Molten Aluminum Degassing Unit are used as lifting devices, which are used to control the vertical movement of the graphite rotor and the U-shaped silicon carbon rod heater heating system, and can be rotated horizontally at 90 °. The hydraulic system is relatively stable. Positioning accuracy.

Heating System

The heating system uses an immersion heater, and a U-shaped silicon-carbon rod covers a cylindrical silicon carbide or silicon nitride protection tube. There is a thermocouple for temperature measurement in the tube, which can realize automatic temperature control, and the power can be adjusted arbitrarily within the range of 2 kW ~ 26 kW. The temperature control system uses a more advanced power integration unit to achieve full-automatic control to avoid the shortcomings of the lack of a buffer stage when the heater is turned on and off. The U-shaped silicon carbon rod heater is constantly affected by the main current during frequent on and off. The heater in the non-buffering stage is easy to age and has a short life.