Over the years, in order to improve the quality of products, the major aluminum processing companies in the world have continuously pursued the improvement of the metallurgical quality of materials. In order to achieve this goal, they have continuously developed melt purification technology to achieve the purpose of improving the purity of the melt. This section will focus on the melt. The development trend of purification technology is briefly introduced.

Melt Purification Technology in the Furnace

Melt treatment in the furnace mainly includes gas refining and flux refining. Due to the limitations of conditions, the development of furnace treatment technology is slow. The vast majority of enterprises basically stay in the furnace gas refining method. Only a few more advanced large enterprises have developed in furnace treatment, and they are more representative. There are two types, one is to insert multiple spray guns or rotating nozzles into the furnace from the furnace roof or the furnace wall to perform gas or powder spraying gas refining. The biggest disadvantage of this technology is that the spray gun is fragile and difficult to seal, so it is not widely used. The other is to install multiple vent plugs evenly at the bottom of the furnace, and the refining gas and refining time are controlled by a computer. This method is more effective in the furnace. Purification treatment method.

On-line Purification outside the Furnace

Due to the limited development of furnace treatment and purification technology, the major research and development objects of major aluminum processing and casting companies in the world are on-line purification technology of melt outside the furnace. Its main development direction is to continuously improve the purity of the melt, and constantly pursue efficient and cheap

Purification technology meets the development needs of aluminum processing melt purification technology.

At present, the degassing devices such as MINT, SINF, and Apu in use meet the product quality requirements. However, these devices are large in size and need to be dried or heated for heat preservation. The operating cost is expensive, and the degassing device is new. The development direction is to continuously improve the degassing efficiency, reduce the operating cost by reducing the metal processing volume, eliminating or reducing the drying of the metal between the castings, and eliminating the heating system.

The online degassing device developed by AdTech is a promising degassing device. The width and height of the device are close to that of the chute. A fixed nozzle is installed at the lower part of the side to supply air. The device occupies a small area and discharges very little dry material. The operation is simple, the degassing efficiency is high, and the investment is small. It is especially suitable for the purification of the melt in the small and medium-sized melting and casting plants.

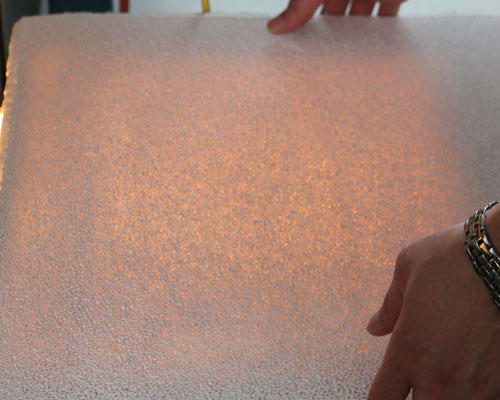

Melt filtration is also an important object for the development of aluminum melt purification treatment. It is also the focus of the development of melt filtration to improve the filtration effect and effectively remove non-metallic inclusions. AdTech’s ceramic foam filter is a very effective filtering method.