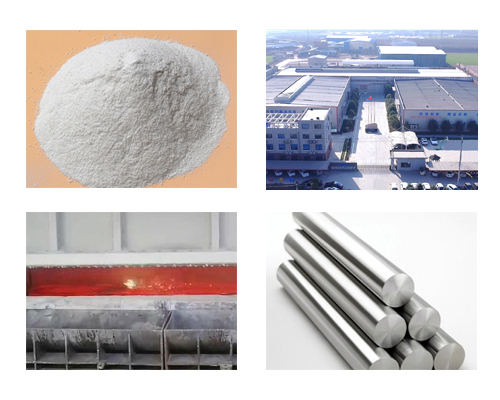

Melting furnace fluxes exist in the form of salt compounds, which are used to purify materials during melting and prevent further oxidation.

The quality of the aluminum cast billets largely depends on the cleanliness of the material.

Aluminum can be processed in two ways. Raw aluminum is recovered through bauxite extract or recycling. Considering that the production of recycled aluminum only needs 5% of the energy required to produce primary aluminum, the ability to recover aluminum is a great benefit. Recycled aluminum is often referred to as recycled aluminum.

The foundry produces recycled aluminum billets from waste. The final product is then transported to the extrusion part of the company for extrusion into profiles. During extrusion, some parts of the profile may have defects and do not have the required characteristics or shape. These parts will then be sent back for remelting.

Since billets will be used for extrusion, they need to meet some quality standards. They need to have sufficient ductility to maintain the press and its components. If the blank quality is poor, the pressing tool may be damaged, which will lead to production interruption. In addition, the blank with poor quality may also cause scratches on the profile surface during extrusion. The billet shall be free of inclusions and non-metallic impurities to prevent such accidents and maintain the billet in good condition.

The best way to keep the material as clean as possible without inclusions and impurities is to remove them from the melt during production. Melting furnace fluxes can be used to remove inclusions from aluminum melt. The refining flux is also used to protect the melt from further oxidation by forming a thin layer on the surface between the melt and oxygen. Another task of the flux is to recover the entrained aluminum from the scum phase and obtain a higher aluminum yield.