By introducing a gaseous chlorinating agent for molten aluminum into the molten aluminum body, sodium is removed from the aluminum. The molten aluminum body contains sodium, and the resulting mixture is passed through a metal filtration system equipped with capable of chemically adsorbing aluminum chloride. As a result of the combination of this gas and filter treatment, sodium chloride forms and adheres to the surface of the filter, thereby reducing the sodium content in the melt.

The metal filtration system is made of granular or foamed material that can withstand the processing temperature, and the surface of the material is covered with chloride-containing salt or salt mixture. It is liquid at the processing temperature and can chemically adsorb aluminum chloride. The sodium dissolved in the melt reacts with the chemically adsorbed aluminum chloride to release aluminum to form sodium chloride, which is combined with the filter material through a layer of liquid salt.

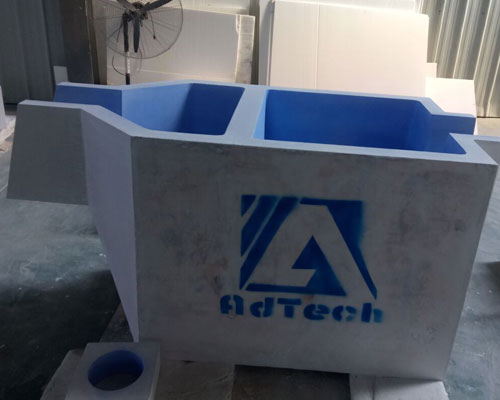

It is advantageous to use refractory ceramics, preferably alumina ceramics or refractory bricks, as the material to withstand the processing temperature. If ceramics are used as the metal filtration system, ceramics can be made in the form of particles or foams. Using suitable refractory materials, a porous or slotted sheet or thick plate can be made into a “substrate”, or a sheet of material can be assembled in the form of a baffle.

It has been found that, especially in the case of ceramic foam materials, the pores are blocked by sodium chloride absorbed on the surface after prolonged use. Therefore, it has proven advantageous to use the filter in a form in which the filter is made of multiple layers of foam, the pore size of which is reduced in the flow direction of the liquid aluminum. By setting the particle size of the granular material, the granular material can be continuously or delaminated in the flow direction of the aluminum melt, and the same effect can be achieved, that is, a longer service life can be obtained from the filter.

In order to prevent droplets of molten salt from being drawn out of the filter due to the flow of aluminum, it has been found to be advantageous to cover the metal filtration system with a filter that physically prevents the passage of droplets. In order to prevent the physical filter from being contaminated, it is useful to pass the gas through the filter in the same direction as the aluminum melt, that is, the gas and metal are introduced into the metal filtration system from the physical filter in the direction away from the side.