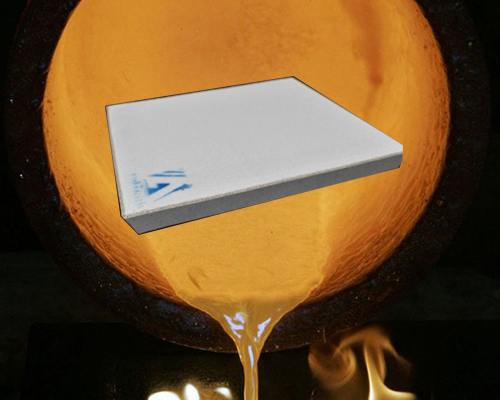

In high-precision industries such as aerospace and aerospace, zero faults and the absolute absence of inclusions in the finished product are basic requirements. In order to meet these basic needs, metal melt filtration is the safest solution, and ceramic foam filters remove the slag so that it cannot reach the mold.

To obtain good molten metal cleanliness, the right equipment and maintaining good process control are the best way to ensure success.

Metal melt filtration is an important part of every manufacturing and foundry industry. Different industries use different materials to filter their finished products. Alumina ceramic foam filters are used in foundries that cast molten aluminum.

As we all know, aluminum is the best material and has many applications. Foundries help shape molten aluminum into different structures to make better use of metal. However, unless you use efficient tools to filter it, the process is still incomplete. The presence of impurities and other unwanted products in the metal will reduce the quality of the metal, thereby reducing the quality of the material cast from the metal. The ultimate goal of the foundry is to make a profit, and high-quality casting materials help achieve this goal.

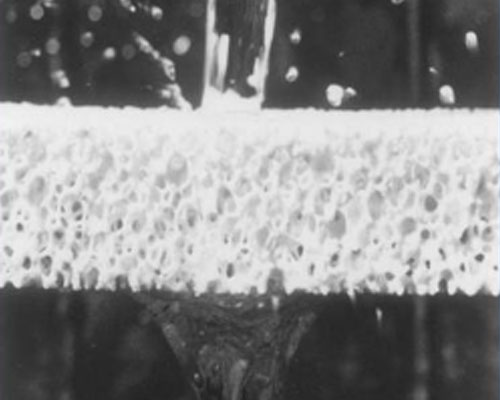

Experiments show that after the use of ceramic filters, the fluidity of molten aluminum is increased by about 25-30%; the rejection rate of castings is reduced by 85%; the casting strength is increased by 10-20%; the pore defects of the castings are significantly reduced; the machining performance of the castings is greatly improved. Because the impurities are filtered out, the hard spots in the casting are also eliminated. At present, ceramic filters have been used in many casting fields such as aerospace, automobiles, machinery, etc. to improve the reliability and performance of casting.

Features of Ceramic Foam Filter Metal Melt Filtration:

Significantly reduced scrap rate

Reduce material costs

The molding structure needs to be improved

Structural mechanical properties need to be improved

Surface condition needs to be improved

Reduce production loss

Corrosion resistance needs to be improved

Eliminate the risk of leaking parts tested under pressure

Limit machining tolerances

If you need more information or support to achieve good molten metal cleanliness, please feel free to contact us. We can help you optimize the process to meet your metal quality requirements.