Metal Transfer Runner System is also called Ceramic Launder, Casting Launder. It is a silicic acid fiber product, and mainly suitable for liquid aluminum distribution and transmission. Casting Launder has higher requirements for heat preservation. AdTech casting launder size can be customized according to customer requirements.

The Ceramic Launder adopts silicon and calcium materials. It is a high-performance insulation material without asbestos. Molten Aluminum Launder has the characteristics of low bulk density, high strength, low thermal conductivity, high-temperature resistance, corrosion resistance, cutting ability. The metal transfer runner system widely applies to thermal insulation of boilers and industrial kilns in power, metallurgy, petrochemical, construction, shipping and other industries.

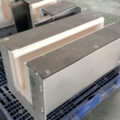

Metal Transfer Runner System

Metal transfer runner is one of the basic equipment for aluminum alloy casting, the main function is to drain the melton aluminum in the mixing furnace to the casting machine.

The traditional casting launder adopts high-temperature resistant castables, and the surface is easy to stick to aluminum during use. It takes the operator 30 minutes to clean the tank, and it is easy to cause damage to the castable. The high-temperature liquid aluminum penetrated into the castable and caused the casing steel plate to gradually deform. After 4 months, the flow channel could not use normally. In addition, the deformed steel plate needs recasting, which requires labor and materials in the maintenance process.

Adtech Ceramic Launder has a reusable or multiple-use lining, adopts new high-silicon molten material. It has certain corrosion resistance, anti-peeling, non-stick aluminum, and no pollution to liquid aluminum. Metal transfer runner can effectively control the cleanliness of aluminum water, has a long service life.

Applications

- Aluminum furnace calcium silicate board bonding, insulation brick masonry, brick seams.

- Liquid Aluminum heat preservation flow channel refractory fiber felt bonding.

- Aluminum flow trough-shaped parts repair.

- High-temperature equipment, casting material gaps, holes to fill, firebrick masonry, other fire insulation board paste.

AdTech metal transfer runner system includes a preform and a glaze layer. The preform has a flowing groove in a longitudinal direction, an upper surface of the flow groove is in an open shape. The casting launder has a simple structure, a fast flow speed and a good heat preservation effect.