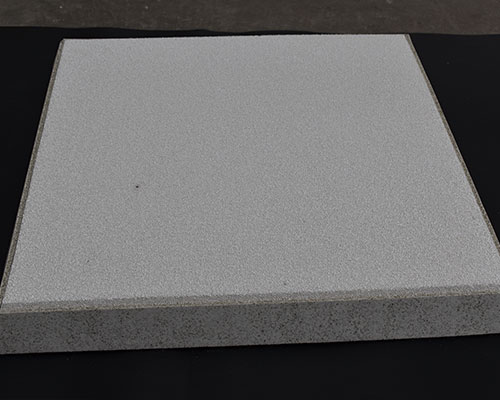

Molten Alu Casting Filter is an effective method to remove inclusions in molten aluminum. The ceramic foam filter molten metal filtration has been verified by users for a long time and can improve production performance.

The oxide film is the non-metallic inclusions and unexhausted gas (main hydrogen) that are mainly formed of aluminum oxide in the ingot. Therefore, the oxide film is a unique non-metallic inclusion type defect in the ingot, but it is different from the slag inclusion. Generally, it cannot be found when the low-magnification test piece and the fracture structure of the ingot are inspected. Special craft samples (upsetting the ingot sample) can only be found.

The oxide film found on the fracture surface of the ingot process sample can be roughly divided into three types: one is light yellow, brown, or dark brown flake oxide film; the other is the surface morphology is similar to the flake oxide film but present bright white “sequins”; one type is round or oval “small bright spots” with silver-white luster.

Among them, the flaky oxide film is a layered layer formed by solid non-metallic inclusions or air bubbles with an oxidized surface. The sequins are layered layers formed by uncompressed loose and air bubbles, and small bright spots are supersaturated solid solutions. Secondary hydrogen bubbles precipitated in the body.

The methods to reduce and prevent the oxide film produced in aluminum alloy ingots are:

In each process link from raw material storage, preparation to smelting and casting, the three aspects of prevention, protection, and refining are started, and corresponding measures are taken to ensure the purity of the metal.

Secondly, the work of preventing and reducing the oxide film should not only focus on removing the solid non-metallic inclusions in the melt, but also on reducing the hydrogen content in the melt as much as possible.

Among the above measures, the most critical should be the following four points:

①Using the most effective combined degassing refining and Molten Alu Casting Filter filtering method for removing slag and gas.

②It adopts a perfect guide furnace and transfer injection technology, and implements casting at the same level.

③Practice high-temperature casting.

④Prevent secondary pollution.