Generally, inclusions, especially non-metallic inclusions, are mixed into the molten aluminum. If such molten metal is rolled after casting or the like and made into a product such as a disc-shaped material without removing the inclusions from the molten metal, the non-metallic inclusions mixed therein may cause defects such as pinholes. In order to avoid this defect, the usual method is to remove the inclusions by filtering the molten aluminum. The molten Alu filter is obtained by bonding aggregated particles such as fused alumina with an inorganic binding material. In the molten Alu filter, the pore size is appropriately controlled, so that stable filtration can be achieved.

In the case of very strict aluminum alloy materials, even a few surface defects have a great impact, and it is necessary to remove even tiny inclusions from the molten aluminum as much as possible.

It is well known that porous ceramic foam materials are particularly useful in filtering molten metal. These ceramic foam materials are particularly suitable for filtering molten metal for a variety of reasons, including excellent filtration efficiency, low cost, ease of use, and ability to use on a disposable basis. These ceramic foam filters are convenient and inexpensive to prepare and can be used once.

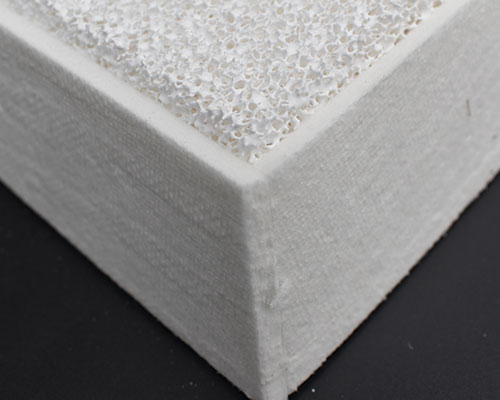

AdTech ceramic foam filter has the principle of adsorptive filtration, which can effectively remove large inclusions in molten aluminum, and effectively adsorb micro-sized inclusions, improve filtration accuracy, and effectively improve product qualification rate and product quality for you. No foam filter piece drops under the impact of thermal stress at 650-720℃, which can effectively reduce the pollution of molten aluminum, and improve the surface quality, product performance, and microstructure of your products.

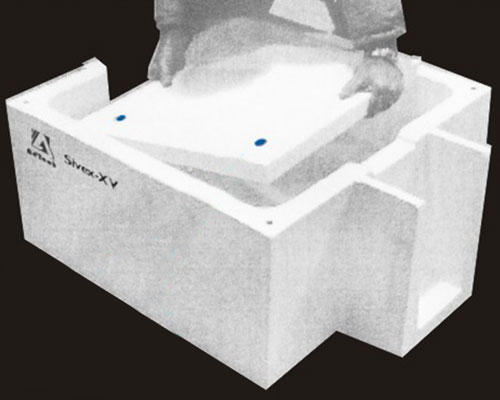

Since the molten Alu filter is designed as a disposable item, it is necessary to provide an effective method to fix the filter in its holder for easy installation and removal. AdTech offers an improved filtration apparatus including a filter chamber, it has a metal inlet and a metal outlet. It is used for supporting the ceramic foam filter. We provide three kinds of sealing materials (fiber cotton, fiber paper and puffed cotton) to better install the filter plate in the filter box and reduce metal leakage.